Porcelain stoneware premises are quite often used. And this is quite explained. High quality material and resulting as a result can satisfy any requirements. Work on the finishing of the premises is sufficiently responsible and is usually carried out by professionals, but it is possible to lay a porcelain stoneware with their own hands. In order not to make widespread errors, the basic rules for performing such work are below.

How can I put porcelain stoneware on the floor?

General information and concepts

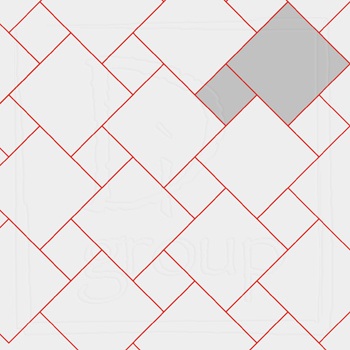

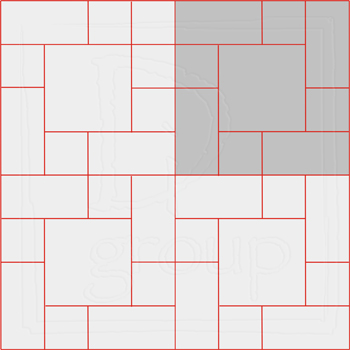

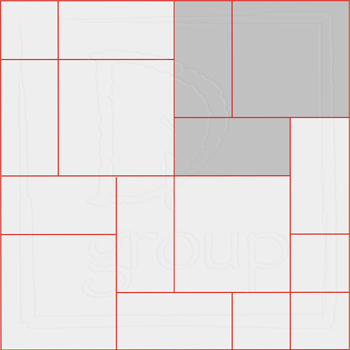

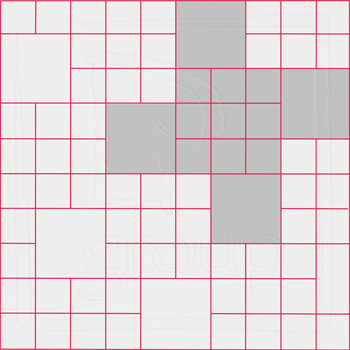

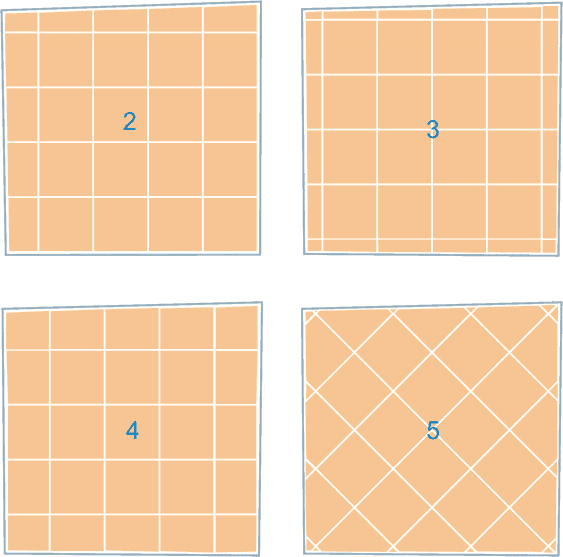

Size, color, shape of tiles from porcelain stoneware are extremely diverse. But even without using special types of porcelain stoneware, it can be postponed by the most diverse ways. Some of them are shown in the drawings below.

|

|

|

|

|

|

|

|

|

Options for laying a porcelain stoneware on the floor |

|

Choosing any of the possible ways to lay a porcelain stoneware on the floor, using simple monochrome tiles, get a beautiful image, especially if you combine different sizes and color of the material.

However, it should be borne in mind that the premises are irreversible, in this case, the installation of porcelain stoneware can be performed in accordance with the figure below.

Options for laying tiles in an indirectal room

Options for laying tiles in an indirectal room It should be remembered that there are several subtleties associated with laying tiles. They are due to the features of image perception and are as follows:

- the tile affects the visual estimate, the large size reduces, and the small increases the size of the room;

- for a visual increase in the width of the room, the pattern is better to lay out across, and for a visual increase in length - along the room;

- you can combine different zones to one whole using a cross-cutting pattern. It is possible to divide into zones using a single pattern.

- light tone tones when laying a porcelain stoneware on the floor visually increase the room;

when the tile is located under the tilt of 45 °, the tile edges must be parallel to the diagonals of the room. The execution of this requirement can be seen in the figure below.

The procedure for performing work on the installation of porcelain

The following material can be considered as an instruction on the installation of porcelain stoneware.

To perform the necessary work, you need the following tool:

Materials

- porcelain tile;

- silicone sealant;

- glue for porcelain stoneware;

- grout for seaming of seams;

- cross;

- primer for processing base;

- water.

Preparation of clamping for laying

Starting work follows from the preparation plan for the installation of porcelain. At the same time, it is necessary to determine how to perform laying, drawing, the method of application and the thickness of the adhesive composition. Possible laying of porcelain stoneware without a seam, jack. The disadvantage of this method is the use of tiles strictly single size, otherwise some of them cannot be used. And also the inability to provide the same length of the seams and the uniformity of their fill.

The advantage of such a method of laying is the possibility of obtaining a homogeneous surface and saving materials. However, the traditional method of laying with seams is optimal.

Before starting working with a tile, its surface must be cleaned from the protective layer, it is usually applied by manufacturers to protect the product from damage during transportation. Most often, technical wax is used to protect, it can be removed with warm water using cleaning products. Paraffin is easily removed using a spatula.

Preparation of the foundation

If the basis where the porcelain stoneware, uneven, then it is necessary to align it. To do this, the screed is made on the surface, the working surface for laying the tile should be smooth and dry, without voids, cracks and dirt. Glossy, shiny surfaces need to sand up to a matte view.

When performing a screed and bringing the floor to a state suitable for laying a porcelain stoneware to the floor, it is necessary to remember the bearing ability of the overlap. Excessive load on them may have unpleasant consequences.

Works can be performed at temperatures above plus 5 ° C, when the heating is on and when heating the floor, it is impossible to lay a porcelain.

Selection of glue

One of the distinctive features of the porcelain is zero water absorption. This is determining when choosing glue, it should provide increased adhesion with the surface. Therefore, the use of cement mortar is undesirable and necessary to use adhesive mixtures with maximum additive polymers.

When choosing glue, you need to be guided by the manufacturer's instructions. In addition, it is necessary to take into account the nature of the base and load in the installation places of the porcelain stoneware, with significant loads, it is better to use mixtures designed for use in such conditions.

Technology laying

When laying a porcelain stoneware, it is necessary to choose the right tool - need a rowing, rubber hammer, crosses, grout. The size of the material used will determine the selection of the trowel - the more the dimensions of the tile, the larrhelter should be a spatula of the teeth. To obtain a permanent width of the seams you need to use crosses.

Before laying a porcelain stoneware to the floor, it should be noted the middle of the floor. For this, the cord is most often used. It is stretched along the long wall. The laying starts from the middle in such a way that along the cord line passed the middle of the whole tile or her seam.

Porcelain stoneware is laid symmetrically, in the edges of the lined surface there are integer or cutting tiles of equal width. That is why the calculation should be started from the middle.

On the protrusions of the walls and external angles, the installation of porcelain is necessary to begin with whole tiles, in the inner corners are mounted circumcised. In the aisles between individual premises, the seams are placed along the transition line from one room to another.

The surface of the laying in niches is distributed so that the cropped tiles of one width were in the middle of the surface or symmetrically at its edges.

First well-mixed to the consistency of thick sour cream adhesive solution is applied to a small part of the area and are aligned with smooth, and then a toothed spatula.

The glue composition is also applied to the opposite side of the tile, after which it must be put in the time not more than 15 minutes.

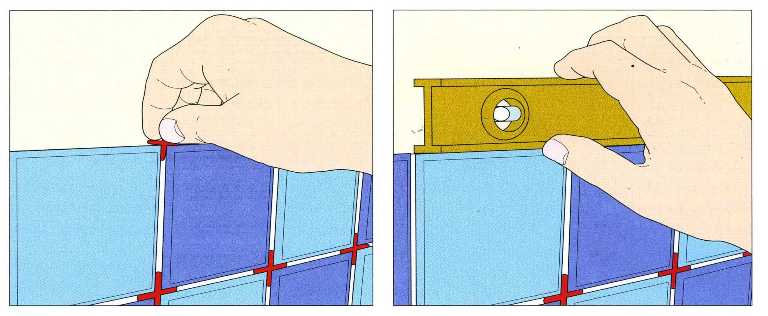

To do this, the tile is placed on the edge and rest in the previously laid. Then the entire tile is applied to the surface with adhesive composition, it must be moved a little from the neighboring, the placed tile slightly pressed into the glue composition. The gap between adjacent tiles should not be filled with adhesive mortar. Crusters are used to ensure a permanent gap.

The level position of the laid tile is checked by the level. It is possible to change the position of the tile (stitch, shift, adjust) within ten minutes. If you have to take a break in the laying of porcelain stoneware on the floor, it should be taken into account that there was a previously laid porcelain stoneware, and the one that stacked later will still settle. So, if they continue to lay them on the same level, then this may result in the difference in levels.

It is necessary to ensure that there is no emptiness in the adhesive. Otherwise, the tile can crack during operation.

The process of drying glue lasts a day, and the complete strength of the seam comes after 3 days.

End of laying

After exposure when the glue is firmly connected to the porcelain, you can grout seams. To do this, the fifth color is used. Although there are also their nuances. A contrast grout will emphasize the drawing, and the tank will make the surface of the facing more neutral and homogeneous.

Before grouting should be checked so that the seam is clean. Any foreign material can spoil the seam and make it difficult to grout. The work itself is performed using a special tool - it is so called grout.

The seam size (cross) for porcelain stoneware 30x30 cm is three to five millimeters. The slots between the floor and the wall, as well as in the places of passage of pipes through the facing, it is necessary to fill with silicone.

The grout solution must be applied to the cladding diagonally relative to the seams. The remnants of the suture aggregate are removed with a clean and damp sponge. A regular washing of the lined surface can be processed in two weeks, not earlier.

You can see the procedure for laying tiles in more detail on the link:

How to assess the quality of work

To assess the quality of the work done for the lined surface, the following criteria are used:

This is how the order of work, technology and techniques for laying a porcelain stoneware look like.