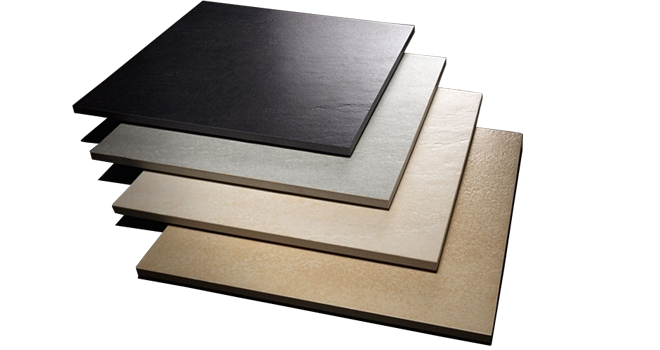

The porcelain tile has long appeared in the construction market, and every day is gaining more and more popularity. This is explained by the excellent quality of the material, its strength, versatility and a number of other positive features.

Porcelain stoneware is ideal for floor facing in any rooms. This process is very responsible and has some subtleties, but the correct preparation and adherence to all stages of work will help to easily and qualitatively perform the floor finish on their own.

For work it is necessary to prepare such tools:

- measuring instrument (roulette, line);

- rubber hammer;

- marker for marking;

- level;

- rubber spatula;

- smooth metal spatula with a width of 30-40cm;

- spatula with teeth;

- tile tiles or Bulgarian for trimming tiles;

- drill for drilling holes;

- capacity for kneading glue and grouts;

- drill with a nozzle for mixing solutions;

- gloves.

Materials

- tile;

- special glue;

- cross;

- silicone sealant;

- primer;

- grout.

Glue for porcelain stoneware must have high clutch of material clutch with base.

By choosing the type of adhesive mixture, the following points should be taken into account:

- This facing material practically does not have moisture-absorbing properties, therefore the use of cement or tile glue is strictly not allowed.

- For external masonry, it is necessary to use glue, which includes plasticizers that give it resistance to low temperatures.

- If the work is carried out inside the premises, choose the adhesive mixture with an increased content of polymer components (latex or acrylic).

Which surface can be put a porcelain stoneware?

![]()

Porcelain stoneware is placed both on a concrete base and on wooden floor or plywood sheets.

For laying on wooden floors, you must perform the following work:

- dismantling wooden floor covering;

- installation of lag in a horizontal position;

- backing the space of space between lags;

- fastening boards with a gap 8-10 cm. With the help of self-tapping screws;

- laying waterproofing material;

- setting the frame of the mesh

- installation tiles.

Laying on plywood sheets is carried out as follows:

- Plywood sheets with a thickness of at least 28mm are located on the lags at a short distance and are tightly attached throughout the base with self-draws.

- After installation, sheets are carefully elevated, cleaned from garbage and ground 2 times.

- When the material is completely driving, you can start laying the tile using polyurethane glue.

Concrete floor

The concrete base should be perfectly smooth, without influx and depression. Most often requires additional floor alignment. First, the layer of waterproofing is placed, lighthouses are installed, and a fill with a self-leveling mixture is performed.

The first stage in the performance of work is thorough surface preparation. This is necessary for two main reasons:

Weight tile

Porcelain is a sufficiently heavy material, and in the presence of irregularities, it is not evenly stacked. This leads to differentials between tiles and angular pairing. For the same reason, it is not recommended to lay this material on a layer of glue more than 1cm.

Tile dimensions

The porcelain tile is made of large sizes, because of which it is quite difficult to evenly fill the space under it, without taking advantage of the comb. If emptiness remains under the tile, these places become very fragile, and when the heavy item falls on them, the tile comes into disrepair.

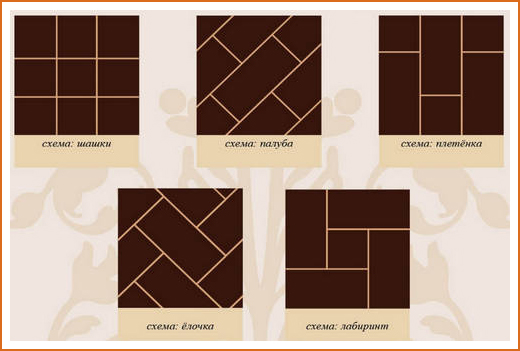

Preparation for filling out the flooring begins with the creation of a project, determining the method of location of the picture and the laying method. Tile must be cleaned from factory dust, and if it has a protective wax layer, it is removed with warm water with the addition of cleaning agents. You can also remove the wax with a metal spatula.

Styling of porcelain stoneware can be carried out in two ways: on seamless technology and with the presence of seams.

Seamless masonry is performed in order to reduce the number of seams and get a smoother surface.

For laying a jack, it is better to choose a large-size tile, since than it is more, the smaller the seams will have a coating. The optimal size of the material for this technology is 600x600 mm.

The gap between the tiles should not be more than 1mm, the remnants of the glue, protruding on the seams, must be immediately deleted.

It is important to understand that the seams between the tiles provide it with additional elasticity, which is required for its preservation when heated and pressing, so this technology is not used if the tile is placed on the heating floor system.

Laying tiles

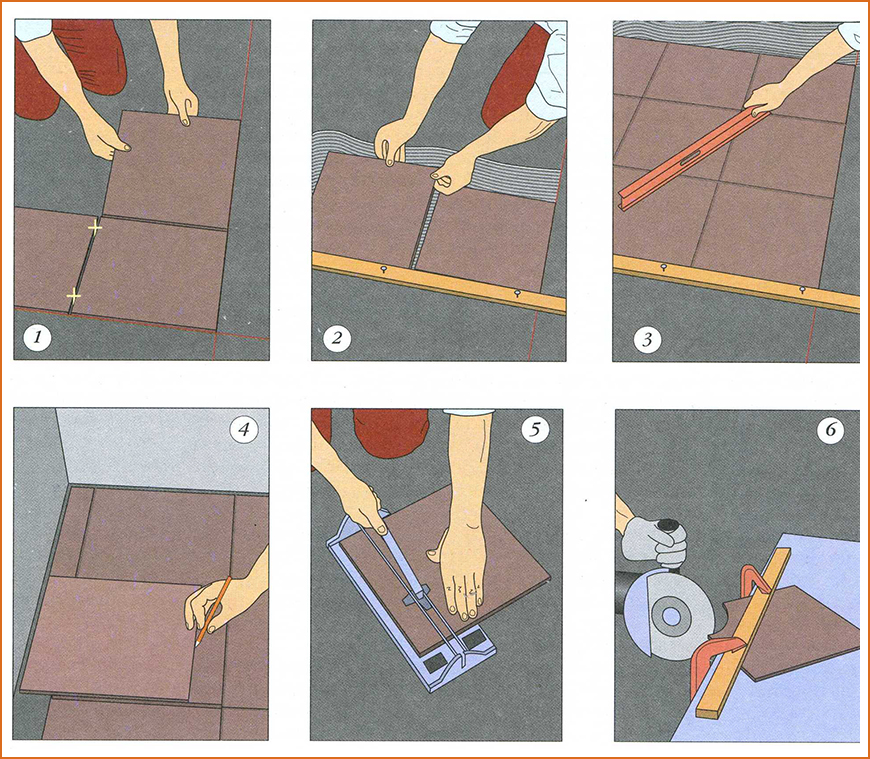

- With the help of the cord, it is necessary to mark the middle of the floor with which the masonry will begin. Starting it is from the middle of the base, since the edges of the surface will need to cut smaller fragments.

- On the base, separately for each tile, glue, whose layer thickness should not exceed 5 mm. This is done with two types of spatulas: the first one evenly distributes the glue, the second creates teeth providing high-quality fastening of the material. The size of the teeth depends on the size of the tile. For example: for porcelain 20x20, it is better to use a spatula with 8mm tooth, and if the tile is greater than 30x30, a spatula with teeth sizes from 12-15mm are used. It is important to have time to lay a tile for 15 minutes until the glue has time to grab.

- The next tile is installed on the edge of the previously laid, after which it sinks to the surface with glue, slightly moves away from the first and pressed. The laid tile is sprinkled with a rubber hammer.

- To ensure the same width of the seams, crossbars are installed between the tiles, which remain there before drying the glue.

- Equality of masonry is controlled by level, after each laid tile.

- If during the masonry process, interruptions are made, it is necessary to take into account that the previously laid tile is settled, and if the new masonry will be carried out at its level, after complete drying of the adhesive, the differences will appear.

Cut and drilling tiles

In order to trim the ceramicrant tile, you need to use electric tiles or a grinder with a diamond circle that best copes with durable material.

If you need to drill holes in the tile, there will be a powerful drill with nozzles: "crown", "Ballerinka" and "Feather", which are designed for work with glass and ceramics.

End of laying

- After drying the glue (as a rule, after 2-3 days), you can begin grouting seams.

When choosing the color of the grout, it is worth considering that the color of the tile tone visually gives the floor coating monophonic and neutrality, while contrasting colors are noticeably emphasized by the drawing.

- Before rubbing the seams, it is necessary to make sure that they are lacking garbage, which can greatly complicate the whole process.

- The mixture is applied with a rubber spatula diagonally to seams, after which it is rubbed with a wet sponge. Excess material is immediately removed.

- If there are slots between the coating and the wall, they are blown by sealant.

Evaluation of the quality of work

To assess how high-quality work is made, the level is applied to the surface. The facing coating should not have drops and convexities, and the seams should be the same width.

Features and advantages of outdoor porcelain stoneware

- Universality

This material can be used to clamp the floors of any premises, both inside and outside.

- Reliability

The porcelain tile is resistant to sharp drops of temperatures, influence of chemicals, and has high strength.

- Low water absorption

The water stonework water pressure indicator does not exceed 0.05%, which allows it to preserve the initial appearance with long-term use of open-air and in strong frost.

- High strength and ability to withstand bending load

These qualities allow the use of porcelain stonewares with a high load on the floor. For example, in production where heavy equipment or car parking is installed.

- Save color

Since such a tile does not have a decorative layer, and the pattern is in its structure, during operation, the tile does not lose color, does not fade and does not erase.

How to choose a tile?

- High-quality tile must withstand drop from a height of equal to its size. To check it put on the edge and let go. If defects appeared - poor quality material.

- The packaging of high-quality porcelain tiles weighs about 18 kg. Little weight speaks of improper quality.

- The depth of the holes and recesses from the reverse side of the material should not exceed 2 mm.

- By buying a tile, you need to trace, so that the whole of it was from one party and had the same color.

- When tapping with a finger, high-quality material makes a deaf sound. For comparison, you can knock on ceramic tiles, the difference must be obvious.

- A lot of important criterion for the selection of tiles is the view of the room in which it will fit. So, for the bathroom and kitchen you need to take the material with a rough surface, which will slide less when in contact with water. But for a corridor or garage, tiles are taken with increased wear resistance.

- When choosing a tile, it is important to take into account the size of the room. In rooms with a large area take both small and large tiles. For small rooms, it is desirable to use porcelain stoneware size of 300x300, since large tiles visually reduce the room space.

Compliance with all the above rules and stages of work will help to put the porcelain tile as much as possible, quickly, and most importantly, without the cost of workshops. The surface of the floor lined with porcelain stoneware looks worthily and does not require much care.

During the work, it is not necessary to neglect the safety regulations, use gloves and glasses that protect their eyes from the ingress of working solutions and dust. Since there is no edging on the ceramicrant tile, it is easy to cut it with its edges, so it is necessary to carry out work as much as possible and neatly.

Otherwise, the process of laying the tile should not cause difficulties even at novice masters.