Porcelain tile has high wear resistance, so ideal for laying on the floor. If you decide to make floors from porcelain in your apartment or house, they did it correctly, because in the end, get a coating that will not need to be repaired for the next 20-30 years. To mount the tile on the floor, it is not necessary to contact a specialist at all. Make quality floors from porcelain stoneware, you can and on your own, and our article will help you.

The tile of porcelain stoneware is manufactured by pressing the semi-dry powder under high pressure and the firing of the finished product in the furnace at a temperature of 1300 degrees. Porcelain stoneware has the following properties:

- Strams resistance.

- Resistance to life.

- High frost resistance.

- Resistance to temperature drop.

- Resistance to the effects of chemicals.

- Preserving the original color with long-term operation.

Tile made of porcelain stoneware, the following types:

- Technical tile - It is similar in its structure to ordinary granite, it has a not very beautiful appearance, for being very strong and affordable. Technical tile is used in rooms with high load on the floor.

- Matte tile - This is a product that has not been polished, so having a lower cost compared to other types of tiles. Matte tile has a higher wear resistance compared to polished, but is inferior in beauty.

- Polished tile - It has a surface polished to the mirror glitter. Due to the complexity of the polishing process, has a higher price than other types of tiles. So that the polished surface does not grieve during operation, manufacturers cover the lacquer tile or recommend to do it after mounting.

- Glazed tile - It has a layer of glaze, applied to the surface and fixed upon subsequent firing. The tile covered with icing.

- Structured tile - It has a relief surface. Thanks to modern technologies, manufacturers have learned to make a structured tile, imitating natural stone, wood and even cloth or skin.

- Lappatled tile - Despite the original name, it is just a tile treated by the method not complete grinding. The surface of such a tile has both matte and polished areas. This type of tile has an original appearance and is often used with non-standard designer solutions.

- Satin tiles - It is made with the use of wax and mineral salts, which are added to the surface in front of the root. The tile has a slightly shiny and not so slippery, like after polishing the surface.

- Tile made by double filling method - It has two layers. The first layer is manufactured using dyes and is pressed with the second layer of the same material, but without paint. This production technology allows saving at cost and produce tiles on the field of an affordable price without losing as products.

Glue for porcelain tiles

After selecting the desired version of the tiles from the porcelain stoneware, now you need to choose glue for laying. Adhesive mixtures for tiles are produced by three species:

The selection of glue for tile from porcelain stoneware depends largely on what room it will be installed. For floors in rooms with high humidity and open-air, it is best for epoxy resin-based adhesive.

Grout for seams

It is also important as a selection of glue, choose the right mixture for grouting seams. Grout for seams is distributed into two main types:

As well as when choosing glue, buying a grout, the effect of water on the tile should be taken into account.

Installation tiles of porcelain

Before starting styling tiles, make sure that you have all the necessary tools and materials. To make you easier to be reconcilized, focus on the list below.

Instruments

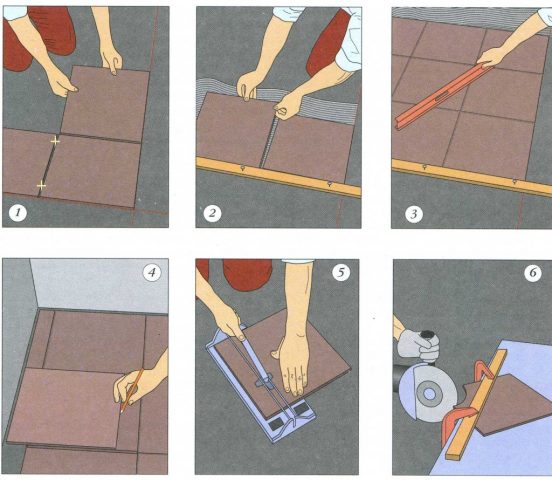

- Platecores or "Bulgarian" with a disk for cutting stone.

- Spatula usual with a smooth edge.

- Spatula toothed.

- Rubber Malka.

- Rubber spatula.

- Rubber hammer.

- Drill with a nozzle for mixing.

- Capacity for glue.

- Level.

- Marker.

- Corolnic

- Yardstick.

- Roller

- Rag.

Consumables

- Ceramic tile.

- Glue.

- Grout for seams.

- Plastic crosses.

- Primer.

- Cement and sand (if the base screed is required).

If all of the above you have in stock, you can safely start working:

The installation process of tiles from porcelain stoneware on the floor is completed!

You can also watch video instructions for laying a porcelain book on the floor:

Installation of porcelain stoneware on "warm floor"

Laying tiles from porcelain stoneware to the "Warm floor" system is not very different from the usual installation on a concrete basis, but still this process has its own nuances that need to be considered:

As the tile is stacked on a warm floor, you can also look in the video:

Installation of porcelain stoneware on the wooden floor

Is it possible to put the tile on the basis of the tree? This question causes a fierce dispute among professional builders. Someone claims that it is possible, someone categorically opposed, but we will not accept whose side. If you decide to install tiles on wooden floors, then pay special attention to the preparation of the foundation:

Otherwise, the installation of tiles on the wooden floor repeats, the usual laying.

How to lay a tile on a wooden base. See also in the video:

If you install a porcelain stoneware on the "warm floor", then when buying glue, be sure to look at the packaging information about whether it is possible to use it for warm floors. Here is a list of adhesive mixes, well-proven to be used for laying tiles for a warm floor:

- Tile glue "Ceresit".

- "Knauf File".

- "UNIS PLUS".

- Typhoon Master NO12

Some masters offer customers to use a method of seamless styling of porcelain stoneware. Allegedly, it significantly allows you to save money on the purchase of a cloud mixture. But this is not entirely true, the savings are obtained very insignificant, but significant problems may arise. First of all, it concerns the displacement of the tile, due to the invisible non-armed eye, the curvature of the sides of the tile. This problem is easily eliminated at the suture method of laying, but during seamless installation, it can lead to significant curvature. Therefore, we advise you to always make styling with seams.

Often you can hear the question: What is the distance between the seams is ideal? It is quite simple to respond to it, the distance between the seams of the tile depends on its size and location: