Thanks to the lightning development of innovative construction technologies, in the arsenal of home masters, planning the repair of the floor covering, in addition to traditional methods, such as the liquidating floor arrangement and finishing tiles, there is another - laying of porcelain stoneware on the floor. Despite the fact that porcelain stoneware is a relatively new material, it has long been sufficient, along with ceramic tiles, is used for mounting floor coatings. In addition, a relatively recent appearance of porcelain stoneware did not prevent him from occupying a solid niche in the construction market, which is explained by its durability, high aesthetic characteristics and environmental safety. However, the process of laying a ceramics is somewhat more complicated by the floor finish with ceramic tiles and is characterized by certain nuances, ranging from the characteristics of the calculation of the required amount of material and ending the screening of seams. Observing these nuances, you will be able to install a high-quality floor covering, which will last as long as possible and, at the same time, will retain the original appearance.

Porcelain stoneware: Features of the floor covering and the rules for choosing materials

Porcelain stoneware is a material made on the basis of a mixture of quartz, field spat, clay and mineral dyes. The manufacturing technology of porcelain means implies the press and the firing of the specified composition in special furnaces, resulting in a tile of high strength, in its aesthetic and operational characteristics, not differ from natural stone. In view of high strength, wear resistance and moisture resistance of porcelain flooring, laying of porcelain stonework, made in all the rules, will be a guarantee of a long service life of the floor covering, which will retain its original appearance.

In view of the fact that the floor is the basis of any room, in the process of choosing an outdoor coating, it is necessary to take into account the functional intention of space. Due to the fact that porcelain stoneware, unlike ceramic tiles, is a more durable and heavy material, its laying is a technologically more complex process.

Carrying out the installation of flooring in residential premises, consider the requirements for one or another premises. If we are talking about a hallway, the flooring should be moisture-resistant, resistant to negative chemical impacts (salt, which sprinkles sidewalks in winter) and pollution, and mechanically durable and wear-resistant.

The floor in the kitchen should be characterized by wear resistance, lack of sensitivity to cyclic temperature fluctuations, as well as resistance to the effects of detergents based on chemistry. Similar requirements are also presented to the floor in the bathroom, which in addition to this should be characterized by resistant to the effects of humidity and the absence of slip. Thus, the porcelain stonewares, for which the above listed characteristics are characteristic, can be used to mount an outdoor coating in the specified rooms.

In addition, matte porcelain stoneware, the difference from polished, is characterized by a rough surface and, in view of high resistance to mechanical impacts and high humidity, can be used to mount an outdoor coating in workshops, boiler rooms and garages, where elevated requirements are presented.

The advantages of porcelain stoneware: its differences from ceramic tiles

Despite the fact that porcelain stonewares and ceramic tiles are outwardly similar, it is not so easy to distinguish them. However, they have significant differences.

Unlike ceramic tiles, porcelain stoneware withstands high mechanical loads, being a high-strength material. Features of the manufacture of porcelain is determined by its specific coloring not only outside, but also inside. Features of the drawing form in the process of manufacturing the tile itself. Thanks to these nuances, the drawing can be seen not only on the surface, but also on the cutting of the porcelain tile. The manufacturing technology of ceramic tile involves drawing a picture only on its surface after manufacture.

In addition, the following advantages are characterized for porcelain stoneware:

- Long operational period;

- Resistance to high and low temperatures;

- Increased moisture resistance;

- Immunity to detergents based on chemicals;

- Wide selection of sizes and colors.

Selection of porcelain stoneware and its preparation for laying

Before purchasing a porcelain stoneware, sketch the surface plan on which laying will be made, and calculate the required amount of material. Calculate the total area of \u200b\u200bthe room and at the rate of 1 kV. Surface meter Determine the total area of \u200b\u200blaying and the required number of porcelain stonework. Calculate the desired amount of material, to the resulting figure, add 8-10% of the total amount of material and so you get the required number of porcelain stoves that must be purchased. This will allow you to insure the errors in the calculations and damage to the material in the process of its transportation. When buying porcelain stoves, make sure that they are identical to their drawing, a sample solution and the format of the entire material purchased.

In the process of selecting porcelain, the intended placement is taken into account in which the installation will be carried out. If it is a bathroom or kitchen, to avoid possible injuries that may occur when water gets into the floor, try to give preference to porcelain with a rough surface.

Subtleties and options for laying a porcelain stoneware on the floor

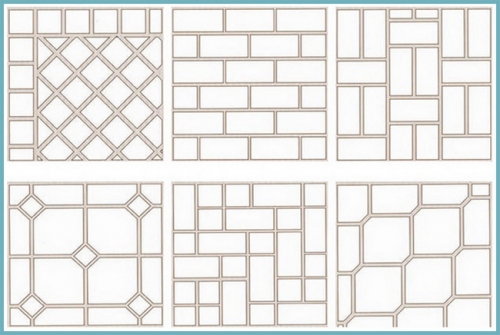

Earlier it was already noted that porcelain stoneware is distinguished by a variety of shape, a wide color palette and a large size of the sizes. Not even using special types of porcelain stoneware, you can lay it in various ways presented in the figure below.

Methods for laying porcelain stoneware on the floor

By choosing one of the presented options and preferring a single-color porcelain tile, you will receive an original image, especially if you combine the tile of different sizes and colors.

Important! If the room in which the installation of the floor covering will be carried out is characterized by an incorrect form, the laying of porcelain stoneware can be made in accordance with the figures presented below.

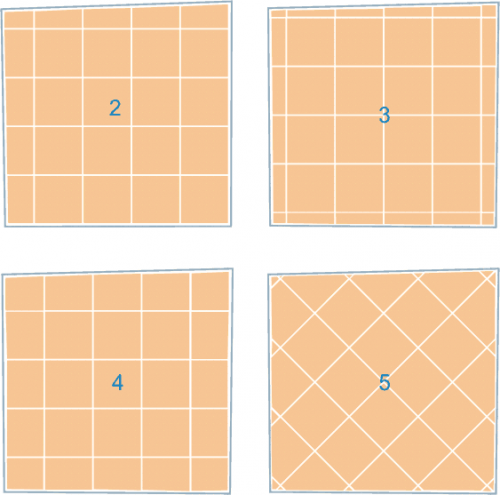

Features of the image perception cause certain subtleties whose observance will be appropriate in the process of laying a porcelain stoneware. They are as follows:

- The size of the tile has a direct impact on the visual estimate of the room: the tile of large sizes visually reduces the room, small - increases;

- To visually increase the width of the room, the designers are recommended to give preference to patterns laid out across, while the drawings laid down along the room contribute to a visual increase in its length;

- To combine multiple areas of the room in a single whole, it is recommended to use through drawing. Separation of the room into several zones is carried out using a single pattern;

- The use of tiles of light tones contributes to a visual increase in the area of \u200b\u200bthe room, while dark colors visually reduce its area;

- If during the installation of the floor covering, you have a tile at an angle of 45 degrees, the edges of the porcelain tile should be located strictly parallel to the diagonals of the room, as indicated in the figure below.

Methods of laying a porcelain book: Procedure

Depending on the type of surface on which the installation will be carried out, there are several options for laying a porcelain stoneware on the floor most commonly used in practice. These include:

- Laying porcelain stoves on false floors, involving the use of special designs for fixing them. This method of laying porcelain stoneware is relevant not only for the installation of false floor, but also ventilated facades. It requires specialized professional skills and is carried out mainly by experienced masters.

- Laying a porcelain stoneware on the floor with special adhesive compositions, which can even be carried out.

The procedure for laying a porcelain stoneware is as follows:

- Preparation of materials and tools that will be required during the work process;

- Preparation of the base for laying plates;

- Laying of porcelain stoves;

- The final stage is the stood of the seams.

Materials and tools for laying a porcelain stoneware

First prepare the following tools:

- Bulgarian equipped with a diamond circle, or tiles;

- Building level;

- Metal ruler or construction level, which are necessary for measurements;

- Simple and toothed spatula, as well as rubber trowel;

- A marker with which the surface markup will be made;

- Drill equipped with a mixing nozzle;

- Capacity for mixing the solution.

In addition, materials will be required from the list below:

- Primer intended for the processing of the base;

- Porcelain tile;

- Glue for mounting porcelain tiles;

- Silicone sealant;

- Grout for seams.

First of all, experienced masters advise carefully consider the installation plan for the installation of a porrite flooring, which involves the definition of the method of laying, the nature of the pattern, the thickness of the glue composition layer and the method of applied. Recently, seamless laying of porcelain stoneware is gaining popularity, which has a visual effect of the formation of a monolithic coating. However, for the installation of floor covering on seamless technology, a special rectified tile will be required, characterized by accurate geometry, taking into account the minimum tolerances. The process of rectification may be subject to a porcelain tile with different surfaces: polished, matte or structured.

The disadvantage of this method of installation is the possibility of using tiles of only one size, as well as the impossibility of ensuring the same seam lengths and uniformity of their filling. However, it is also characteristic of this method - its use allows us to provide a homogeneous surface without seams and save the materials used. Despite the advantages of the method, many prefer the traditional method of laying.

Before starting installation work, the surface of the tile is cleaned from the protective layer applied by manufacturers to preserve its integrity. Most often, technical wax is used as a protective layer, remove which can be warm water with detergent. If paraffin was used as a protective layer, it was removed using a spatula.

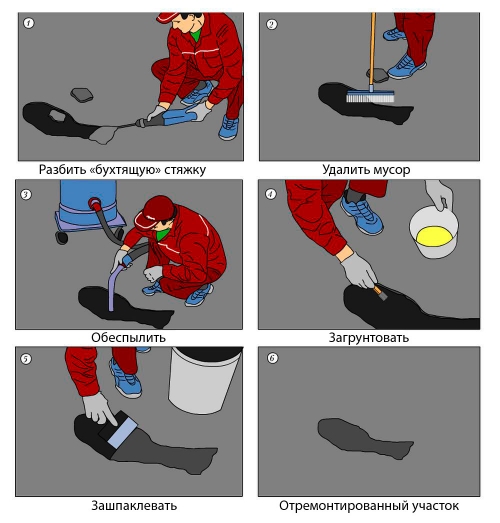

Foundation Preparation: Main Nuances

Laying of porcelain stoneware can only be carried out on a perfectly smooth surface with sufficient carrier capacity that will be the key to the quality of the floor covering. In the case of irregularities on the surface, they will cause difference in the thickness of the laying layer and the subsequent difference in voltages on the coating, which will lead to a deterioration in the tiles with the base. In this regard, before laying a porcelain stoneware on the floor, the price of which depends on the quality of the material used, produce cleaning, dedusting and primer of the mounted surface.

Important!If the installation of porcelain stoneware is carried out on a wooden surface, make sure that it does not spring under the weight of a person. In case of defect detection, make a packing of a reinforcing mesh on a wooden surface.

Selection of cerarmory styling glue

Porcelain stoneware is a material that is characterized by zero water absorption, and this must be taken into account in the process of selecting the adhesive mixture. In view of the fact that the glue for styling of porcelain graffiti should differ in an increased degree of adhesion with the surface, for the installation of porcelain stoneware to the floor is prohibited from the cement solution.

Important! The cost of laying porcelain stoneware on the floor will be slightly higher if you use glue mixes characterized by a large percentage of polymer additives, but this option is most preferable in mind its high reliability.

Choosing Cerambrain Styling Glue Take into account the nature of the ground that will be installed, as well as the recommendations of the glue manufacturer, presented in the instructions.

If the installation of an outdoor coating is made in a corridor or another room with high pendant people, specialists are recommended to prefer more rigid adhesive compositions, for example, a two-component glue on a cement basis, which contains latex and epoxy resins. For laying floor in rooms with high humidity, use elastic glue with high elasticity.

How to make seamless styling of porcelain stoneware?

This method of laying is relatively new and requires compliance with certain technological nuances.

- Seamless laying of porcelain stoneware implies the use of large-sized porcelain stoneware size of at least 600 x 600 mm. Observing this requirement, you can minimize the number of seams;

- Within the framework of seamless styling of porcelain stoneware, the seams are a kind of buffer, which softens the load elevated to the porcelain band surface. The grouting formulations used for the final processing of the seams in the process of temperature drop are compressed and expanded, which prevents the flooring cracking. In case of neglect of these materials, the floor covering will soon fail, losing its initial characteristics;

- Laying of porcelain stoneware on seamless technology can be carried out only in a certain temperature range from +5 to +35 degrees;

- In the process of laying a porcelain stoneware, it is possible to leave a gap of no more than one millimeter, which is filled with a special thicker composition and epoxy resin, which is selected into tile tone;

- If the sketch of the drawing of your floor covering assumes the creation of a symmetrical pattern, the installation of the porcelain tile is better to start from the middle of the room, stretching the twine along the symmetry line;

- Application of glue mixed to a sour cream state is carried out on a small portion of the mounted surface and in the subsequent spatula is resurrected. It is important to eliminate the formation of bubbles;

- Make sure that in the adhesive layer between the floor and porcelain tiles, the emptiness is not formed, which will prevent the tile cracking during operation.

- The glue surface obtained during the laying is treated with a toothed spatula;

- Setting the clermers on the glue composition, check the correctness of its laying using the construction level;

- The distance between each subsequent laid item should be no more than 3 mm. This laying rule is common for all types of porcelain tiles, with the exception of edged porcelain stoneware, when the gap is almost impaired and does not exceed 1 mm;

- The porcelain coating, laid in accordance with the rules described above, leave 3-4 days before complete drying of the adhesive composition, after which it can be operated with maximum loads.

- The final stage of installation of a porcelain-bound floor covering - stood the seams. In the process of selecting the color, the grouts take into account several parameters - the color of the tile and the width of the seam. In most cases, experts recommend to give preference to the least marked gray tones of grout.

- For grouting tile seams, a rubber spatula is used, which is also used to remove excess ground composition.

Assessment of the quality of installation work carried out in accordance with the following criteria:

- The surface of the flooring from porcelain stoneware should be characterized by the absence of convexities and depression;

- The surface of the floor covering should create the impression of a single harmonious composition.

Laying a porcelain book on the floor video