Porcelain stoneware is a special class of facing ceramic materials whose specific feature is enclosed in high strength and almost zero porosity. This is a big plus for an artificial stone, but in some aspects of its characteristics are forced challenges to the laying. The presented guide will help to figure out how to lay out the floor stoneware on the floor - the base subject to large loads. Consider all the questions: from the preparation of the surface to the grout of the seams and the care of the tile.

Fast navigation on the article

Surface preparation

Facing should precede compliance with certain surface requirements for the installation.

Deformational seams

To compensate for the deformation of the elements of the building and avoid the coating disorder, the deformation seams are arranged in concrete floors. They are divided into three types.

Perimetral

It is arranged along the contour of the walls and the columns in order to limit the effect of deformation of the structural elements on the screed. For this, around the perimeter of the room before the pouring of the screed is laid a strip of a compressible material, usually polystyrene foam 1 cm thick.

Temperature

The screed in the process of operation is inevitably cracking. To limit the appearance of cracks, set temperature seams. It is recommended to cut into squares, but in any case the width should not be less than a length of more than one and a half times. The usual size of squares is 6x6 m.

Dividing

We need to limit mechanical loads associated with rapid evaporation of moisture in the first half of the year of the operation of concrete. Performed on the square up to 30% screed. The width of the gaps, as a rule, is at least 5 mm.

The last 2 types of deformation seams are used mainly in large commercial premises, or with an area of \u200b\u200bmore than 25 m². For external coatings, at least every 9-12 m².

Glue for tile

Characteristics of mixtures

According to EN 12004 and EN 12002, adhesive for classified on the basis of chemical composition and special characteristics:

- cement (brief designation of the letter C);

- jet (R);

- dispersion (D);

Cement adhesives are most common, they can be recommended for laying in most situations. Epoxy resin-based reactive compounds have very high adhesion and are used to glue ceramics with metal, wood and other complex bases. When cladding on the concrete base, they are inappropriate - too expensive. Dispersion for concrete are also not suitable. They, though high-adhesive, do not penetrate deep into the surface. But this quality is valuable.

Each type of compositions is divided into classes:

- basic (denotes number 1):

- superior (2):

- quick-which (F);

- long-term (E);

- elastic (S1);

- super elastic (S2);

- resistant to vertical sliding (T);

The choice depends on the operating conditions and coating. The type of glue is indicated on the package. For example, when laying on waterproofing or warm floor, C2S1 is a cement superior elastic. This type includes Ceresit CM 17, Litokol Superflex K77, Sopro No. 1, Knauf Flex.

The correct selection of glue is crucial for cladding. The use of one or another composition depends on various factors:

- base structures (standard - cement screed or plaster, non-standard - plasterboard, old tile, waterproofing, wood);

- tile format (the greater the size, the higher the adhesion indicators of the adhesive);

- purpose (walls / floors / inside / outside of premises);

- time to run the room in operation (at low temperatures or limited time it is better to use quick-conchive C2F grade glue, such as MAPEI Granirapid);

- weather conditions in the process of cladding;

![]()

Work with glue

Almost zero water reducing of porcelain stoneware dictates special requirements for the application of the composition. An ordinary ceramics is enough of one-sided blasting - most often on the surface of the base. To qualitatively put ceramic granite, we recommend double-sided applying: on the screed / plaster and on the tile. It provides good adhesion and lack of emptiness under ceramics. Voids can lead to the appearance of cladding cracks due to a blow or a large point load either when accumulating and freezing in them moisture.

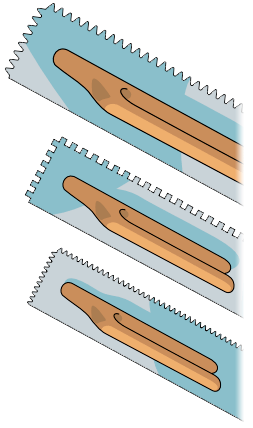

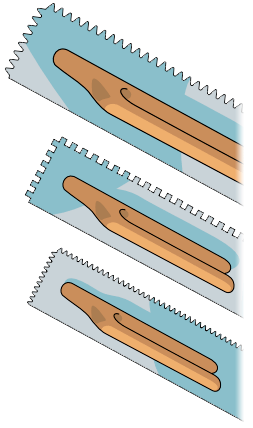

The glue is applied with a smooth metal spatula, after which the surplus is cleaned with a "comb" with a spatula with teeth. The tool format, like the size of the teeth, depends on the dimensions of the porcelain stoneware. On the back side of the tile is quite thin coating with a mixture - "on the Sadir", only the glue had a tight contact with the mounting base.

With internal floor laying in residential premises, the contact of the mounting side of the tile and glue should be at least 70% of the entire surface. "Commercial" interior floors and outdoor any type require one hundred percent applying a mixture on both surfaces.

Laying tiles

Shvov width

The size of the jacks between the tiles depends on the size of the porcelain stoneware and temperature regime. Depending on the width of the gaps, they say stacking:

- with open seam - width more than 2 mm;

- with minimal joint - 1-2 mm;

- job is less than 1 mm;

An open seam facing is recommended for outdoor tile work and for internal when the heated floors are cleaned. High temperature and its oscillations affect the deformation of the joints. Therefore, in order to compensate for the movement of the seam design under the specified conditions increase. Another reason for wide joints is a geometrically poor-quality tile and its non-reclamation. Cerambulanits "trapezium" forces to play seams, too narrow gaps can lead to layering plates. The laying of the tiles from different parties leads to this.

The minimum seams are arranged in the interior under operating conditions at room temperature. The width of the joints increases with the consolidation of the tile. For example, for a porcelain stoneware less than 300x300 mm appropriate seams with a width of 1-1.5 mm.

Laying porcelain stoneware is not dependent on the size of the plates. It is practiced - with treated edges. At room temperature and the absence of sudden temperature fluctuations can be laid at all without seams. Still, it is better to arrange at least semillimeter intervals - they do not spoil the visual monolithization of the facing and compensate for the influence of other factors.

Responsibilities of Tiler

The customer, without being a professional, sees only "decorative" moments. Therefore, the duties of the Tiler includes informing about the possible problems associated with facing material and the state of the base.

Specialist is obliged:

- inform the customer about the presence of tonal, calibration and other ceramics defects;

- pay attention to the existing or potential problems of the surface structure prepared for laying; ask profile issues that prevent the decline in reliability and durability of the facing;

- work in accordance with project requirements:

- stop according to the layout type provided;

- keep laying in a single direction (indicated by the arrow on the back of the porcelain stoneware);

- observe the specified width of the seams;

- observe the relevant standards standards.

Laying ceramic granite

Putting ceramic granite with your own hands although it is not easy, but under the power of any homemade crappy. Work is broken into several stages:

- placement of the room;

- laying of the lighthouse row;

- facing the rest of the surface;

There is no need to pre-pump the porcelain stoneware in the water. If there is dust on the mounting side, it is enough to dip each tile into the water.

Place the floor with the level, roulette and painting cord. Marking includes checking the plane and geometry, the exhibition of beacons, signaling about the height of the future gender and the stretching of the bearer cords that specify the direction of laying.

Lay the whole tile on the site with the greatest viewing, leave the "draft" places. To make a narrow trimming on the opposite edge, the laying is better to start evenly from the center to the sides.

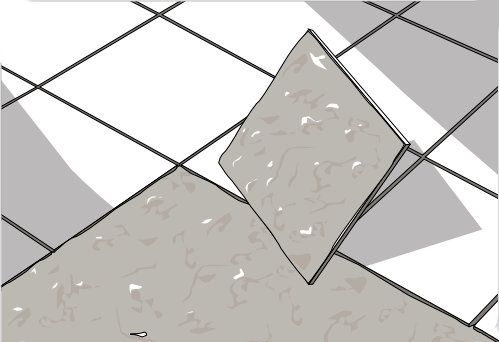

There are three main types of slab layouts:

- Seam in seam;

- Rotor;

- Diagonally.

In the process of laying, every step is important, but special attention is paid to the first row. From how qualitatively it is laid, the final result is largely dependent. To observe the same seams, use remote crossings and / or clins. The latter are needed to adjust the gaps in the case of poorly calibrated porcelain.

The layer should be low: by pressing and (sometimes) with a rubber hammer (light tapping). Visually and tactically check the lack of drops between the plates - "steps". Plane Control the level and rule. There should be no gaps between the rail and tile. Otherwise, remove the porcelain and add / remove the glue.

Stacking video lesson:

Observe the technology of using the adhesive mixture. On the package, the life of the finished composition is indicated, do not try to exceed it, focusing on the plasticity of the glue. The light crust that covered the mixture after a while indicates that the material has lost its original qualities, and adhesion with tiles is already very reduced. And this, despite the deceptive appearance of re-mixed glue. Even more reduces the adhesion to the subsequent mixing of the mixture with the addition of water.

On the lifetime of the adhesive depends on the area of \u200b\u200bits one-time application. The mixtures are different, as well as the format of porcelain stoneware, but on average, at a time, rinse about one square meter. Adjust the position of the plates, try for 10-15 minutes, later attempts to correct the situation lead to violation of adhesion. The lifetime lifetime can be very different in non-standard conditions, for example, at high temperatures or porous base with strong moisture absorption.

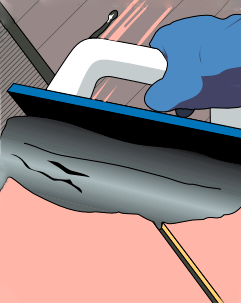

Trim Tile

Laying of porcelain stoneware on the floor does not do without trimming. This is done with a stoveturized (manual mechanical or electric) and a grinder. It is more expensive, so at home, working with your own hands, we recommend using mechanics with powerful beds and guides. A cornerless car with a diamond disk in the cafél is needed for any non-standard trim.

Shutkish seams

Close up of joints between tiles with special smears. The glue used for laying is not suitable - except for the obvious lack of aesthetic appearance, its structure of the coarse-grain.

Do not forget about deformation seams, if any. They are closed with either silicone or using two components:

- elastic filler; They may be, for example, polyurethane foam or polystyrene foam; The strip size must be less than the depth of the seam to remain a gap to expand the filler;

- superficial sealant (based on polyurethane or silicone); The main characteristic of the material for sealing deformation gaps - elasticity;

Let's return to the grout of the seams. According to the standard EN 13888, the Fugue is classified by chemical composition:

- cement (denotes CG);

- for ordinary seams (1);

- for improved seams (2);

- reactive (epoxy, denotes Rg).

Additional designations have grouts with increased abrasive resistance (AR) and reduced water absorption (W).

Silicone grouts belong to sealants.

- For household premises fits grade CG2.

- For premises with high humidity (bathrooms, showers, pools) and internal works - CG2 W. class

- Commercial premises - class CG2 AR.

- Objects with increased hygiene requirements and chemical resistance (kitchen apron, tabletop, food production, hospitals, shops).

Cement maps

Due to the relative cheap and a huge tone diversity, cement grouts are much more popular than others. We recommend using the material of European manufacturers. Many mistakenly consider the choice of a secondary fugue, without realizing that a bad melting spoil after a few months, even perfectly made facing.

Since laying of porcelain stoneware is most often in places with the lack of perfectly dry conditions, acquire the smelting, which includes water-repellent and antifungal components. Additionally, to increase the waterproofing of the joints helps specialized impregnations, which cover the sutures. Depending on the degree of penetration of deep fugi, two classes of impregnates are distinguished:

- polymer varnish; penetrates deep, providing good waterproofing;

- hydropobicator; impregnates the surface of the smelting, damage to the top layer of the Fugue leads to hydrobaric supports;

Apply the impregnation with a brush, pre-occupying the protection of the tile from the composition. Otherwise, stains can remain on the ceramicar. Technology requires double applying: process the second time in a day.

I choose a grout mixture, remember that the tone of fresh grout differs from the shade of the stagnant. Often the differences are available even between the actual lull and shown on the package. If the color of the material is extremely important, experiment in a small area.

It is possible to start the smelting of the seams not earlier than a day after the cladding. Exception is the use of quick-sized glue (you need to wait at least 3-4 hours after laying). The joints must be thoroughly cleaned from the binding mixture, the tile is washed. The grout is kneaded according to the instructions on the package.

It is possible to start the smelting of the seams not earlier than a day after the cladding. Exception is the use of quick-sized glue (you need to wait at least 3-4 hours after laying). The joints must be thoroughly cleaned from the binding mixture, the tile is washed. The grout is kneaded according to the instructions on the package.

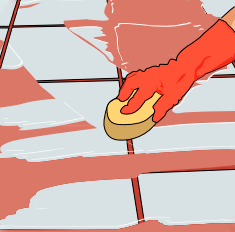

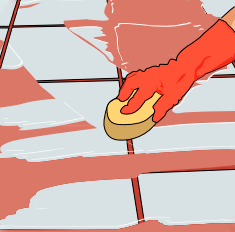

For fugging, they are either a cooler, which is applied to the seams. The mixture should fill out at least two thirds of the depth of the gap, otherwise there is a risk of destruction of smelting. Apply the composition with an effort, empties are processed again. Remains immediately clean the spatula. In one approach, you can handle 0.5-3 square meters. The specific area depends on the type of grout and manufacturer.

It is easiest to work with glossy porcelain stoneware. Matte, and even more so structured to lift the harder - a fugus penetrates into the pores, from where it is washed with difficulty. In such cases, it is more convenient to wash the mixture with a damp kitchen sponge with an abrasive surface.  Conduct to the condition of the seams with a wet foam sponge. Some manufacturers produce special needs, but their use is not fundamentally. It is important to observe the diagonality of movements towards the joints, "parallelism" flushes a fugue from the gaps. Before using the sponge, a round rubber spatula or 8-10 mm cylindrical cable, which smoothed and compact the fugue layer is used. As a result, the seams are obtained with a homogeneous deepening and a smooth surface. Finally, the cladding is washed after 10-20 minutes, when the grout will be filled.

Conduct to the condition of the seams with a wet foam sponge. Some manufacturers produce special needs, but their use is not fundamentally. It is important to observe the diagonality of movements towards the joints, "parallelism" flushes a fugue from the gaps. Before using the sponge, a round rubber spatula or 8-10 mm cylindrical cable, which smoothed and compact the fugue layer is used. As a result, the seams are obtained with a homogeneous deepening and a smooth surface. Finally, the cladding is washed after 10-20 minutes, when the grout will be filled.

Epoxy putty

Consist of two components: fillers and resins. Quality of seams, seamless fuga of this type, is an order of magnitude higher than the cement plug-in. The material is very dense, waterproof and chemically inert to most chemicals.

In use, epoxy is much more complicated than the familiar grout. Mix the components should be accurately before gram. Due to harm, it is advisable to work in rubber gloves. For one approach, no more than the square of the cladding is treated, the movement of the spatula does not differ from the already described. The life of the finished composition is no more than half an hour.

Indentant seams are abundantly wetted with water with the help of a "hairy" kitchen sponge until the emulsion is formed. This is done with caution, so as not to wash the mixture from the seams.

The liquid residues of the mixture are removed with a sponge of rigid cellulose. When the sponge is impregnated with a resin, you need to replace it with a new one. Litokol has special sponges for epoxy grout, they are more expensive, but more durable.

It is necessary to wash off the epoxy grout before the start of frozen, otherwise problems will arise. The remaining raid is washed with water with the addition of 10% ethyl alcohol or special detergents (for example, Litonet GEL).

A little about Silicone

The use of silicone leads to the latter in the ceramics. Without waiting for setting, it is removed by a solvent (gasoline, toluene, ethyl acetate). The frozen material on solvents does not react, get rid of it only mechanically, and with the risk of tile damage.

Tile care

Little to put porcelain stonewares, the durability of the facing in directly dependent on the proper care of the tile. Styling ceramics is crowned with cleansing from the mixtures used during operation and testing for mechanical damage. Sand pieces are the strongest abrasive, and if you do not remove them, they scratch the surface and will collect dirt.

For cleaning, we recommend using acid tools, such as FILA DETERDEK. The degree of dilution is selected based on the structure of the ceramic granite: for cleaning the glossy surface, you need 3 liters of an acidic solution by 100 m² in proportions 1 to 10 (0.5 liters. Fila DeterDek for 5 liters. Hot water), structured - 6 liters of 100 m² In proportions 1 to 5 (1 l. in 5 liters. hot water).

Acid cleaning can be carried out at least two days after the seams are grouting. All metal and marble surfaces need to be protected with adhesive tape.

The process is divided into steps:

- moisten the floor with water to achieve a moderate influence of acids on ceramics;

- with the help of a mop or sponge uniformly distribute the agent;

- leave for a few minutes (time depends on the degree of pollution);

- vigorously wipe the cutting surface of the facing by abrasive sponge;

- remain remnants Remove with a dry cloth;

- clean hot water wash the floor.

Possible residues of the influx are removed by re-procedure, already using more concentrated substances. Current care lies in periodic cleaning of porcelain with water. In the event of oily spots or hard dirt, please contact special needs.

A certain complexity of cladding with a stoneware forces once again to pay attention to the observance of the standards of preparation, laying and care for tiles. You can praise you for the decision to perform work with your own hands, but you need to warn with ignoring recommendations. Remember that the base should be durable and stable, and glue - appropriate application conditions. The choice of ceramic granite is also due to the specifics of the material operation. It is unreasonable to put smaltized porcelain stonewares, as well as the simplest matte - in the status room.

Comments Powered by Hypercomments