The warm floor, which is even relatively recently unattainable, being an exclusive element of housing arrangement, has now become a fairly ordinary thing available at the price, friendly, easy to install. Advanced technologies for the production of electric heating floors allow you to obtain not only an effective energy-saving room heating system, but also to equip it without any problems.

Comparative characteristics of electric heat floors

Electric warm flooring for housing heating is recommended to select this way, based on the characteristics of a particular apartment or an individual house, so that the selected system can generate the required amount of heat, was economical for electricity consumption and did not imagine special difficulties during installation.

Easy styling is especially important if you decide to equip the electric warm floor with your own hands.

The heating system "Warm floor" can be used in any room and under any floor covering, in addition, it can be used for external work.

The types of warm floors, submitted at the moment in the building materials market, have a different configuration and a wide range of power indicators, which simplifies the moment of choice and allows you to purchase a heating system, the most fully appropriate needs of your housing. Varieties of electric warm floors:

- cable

- cable on the base

- film infrared

We suggest to consider each type in more detail.

The easiest cable version

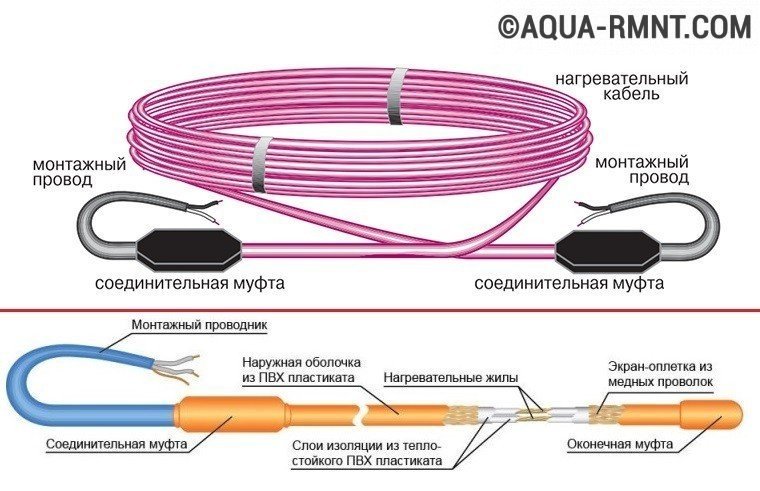

The main functional element of the cable heat device is the heating element in the form of a wire that transforms electricity to heat.

Heating cable of a warm floor consists of two conductive veins, fiberglass reinforcement, polyester film, copper conductor, aluminum screen and PVC protective layer

Of all the types of electric floors, the cable heating system is the most complex and time-consuming for installation, as it requires careful laying of the cable with a given step and the mandatory finish stage - the fill of the screed. The additional layer of the screed of a thickness of about 5 cm leads to a tangible loss of the height of the room, which acts as a fundamental point when booking this type of heating in the apartments of high-altitude houses. Another significant lack of cable warm floor is the impossibility of styling under furniture and plumbing devices. However, this type of electric floor has indisputable advantages - the heating cable can be used to install in rooms with a complex perimeter, as well as for heating the exterior elements of the private home - roofs, and wastewater.

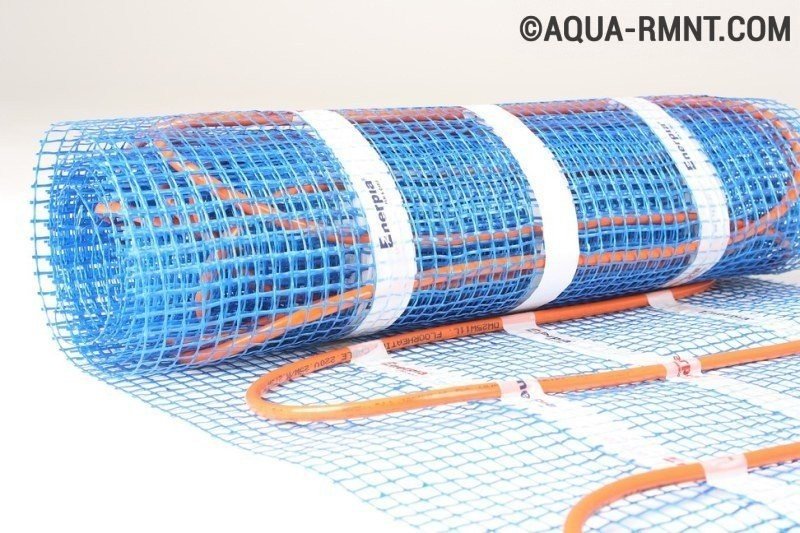

The cable warm floor on the ground has a small thickness and is a mesh mat, which is fixed with a heating cable with a cross section of about 2.8 mm. Compared to cable, this type of warm floor is simpler in installation, since the heating wire is laid and fixed on the base, so the laying process is in layout and fixation of mats.

A convenient option for installation is a warm floor in the form of heating mats consisting of a mesh base and a fixed cable.

The cable floor on the grid is the most suitable option for installation under the tile, since the thickness of the adhesive solution layer is quite enough so that the mats of the warm floor are in its thicker. In the event that this type of electric floor is installed under laminate, carpet or linoleum, the fill of the screed will be required, but it will be small enough - about 3 cm. It should be noted that the cable warm floor on the ground is not recommended to be laid in those areas of the room where it is assumed Placement of furniture or plumbing equipment.

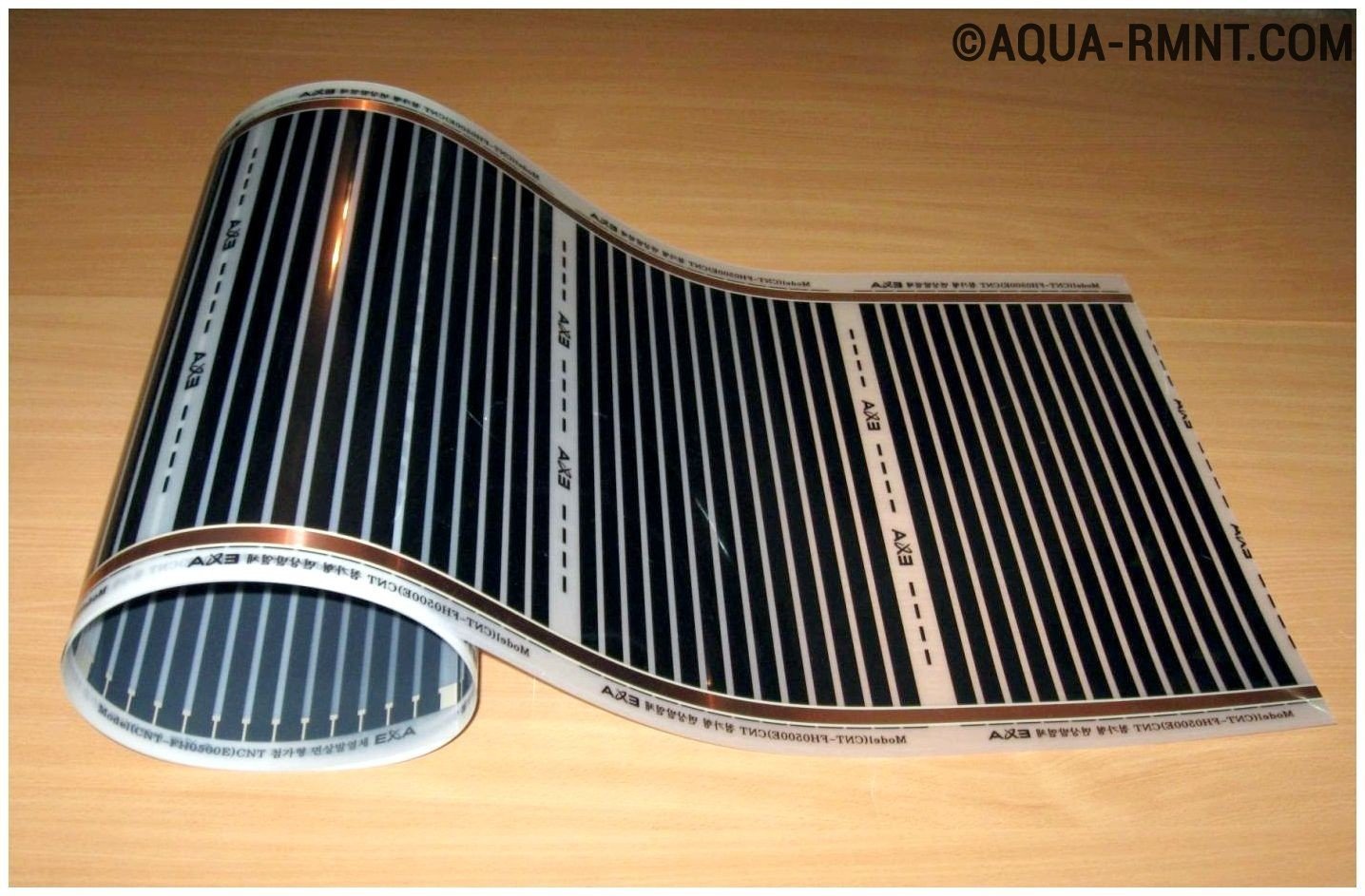

Infrared film

Infrared warm floor is made in the form of a two-layer film with carbon heating elements and has a thickness of about 0.5 mm, which allows you to preserve the height of the room in a constant form, unlike other warm floors.

The infrared floor consists of two layers of electrical polyester, between which coal heating elements and conductive copper foil are placed.

Moreover, infrared gender is the most energy-saving among other heating systems - during its operation, about 60% of electricity is saved. The laying of electric heating floor with infrared heating elements is the most simple of all possible - the film strips are spread on the base of the floor without taking into account the design of furniture, and the flooring is installed immediately, without the time-consuming process of filling the screed.

It is important to know: film infrared warm floors can be installed on any surface - horizontal, vertical, inclined due to the so-called, "dry installation".

How to make an electric warm floor independently with the smallest financial investments and labor costs, having received a high-quality heating system? The answer is simple - you need to choose the optimal version of the warm floor, which according to the technical characteristics will meet the needs of your home, and its installation will not be much difficult if it is installed on its own forces.

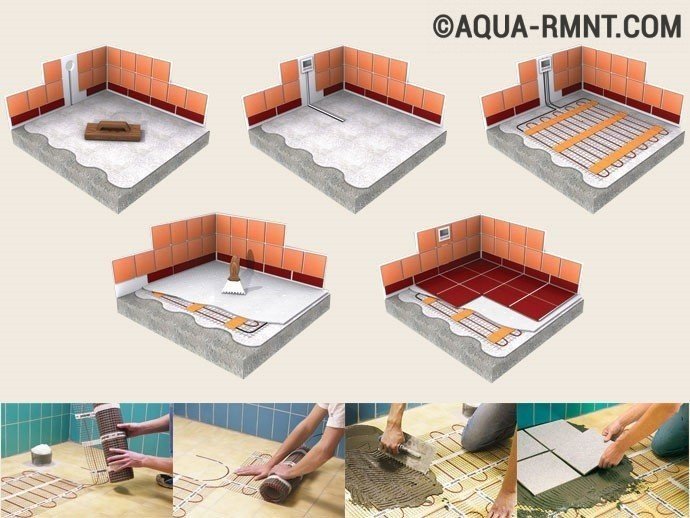

Step-by-step instructions for mounting

Electric warm floor in the form of heating mats is optimally suitable for stacking under the tile

Preparation of floor base

Since the installation of electric heat floors belongs to the category of "chisty" construction work, this process is made after the walls and ceilings are plastered, the screeds are covered - that is, the "rough" stages of construction are completed. It is characteristic that at the end of these stages, the base of the floor, as a rule, is covered with a layer of dust and dirt, there are fragments of a frozen plastering and cement mortar. To clear the surface of the base for the installation of a warm electric floor, it is necessary to remove the hard slices of the solution with a spatula or use a special solvent, then, moisten the floor with water and mix the remains of building mixtures, garbage, dust using a brush.

It is important to know: so that the warm floor function properly, without overheating and short circuits, the base surface is a concrete base, must be even, without significant drops in terms of level.

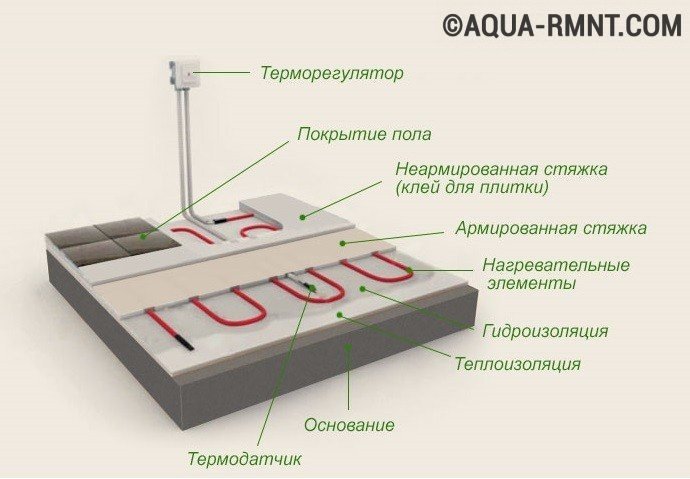

Laying outdoor heat insulation

Laying thermal insulation on the warm floor is necessary to reduce heat loss and creating directional heat fluxes

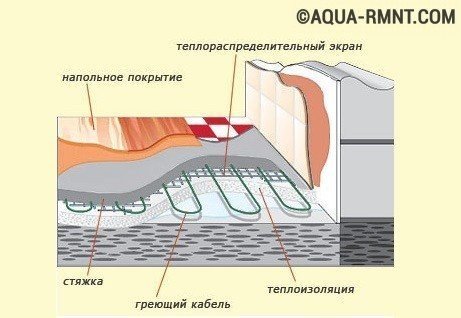

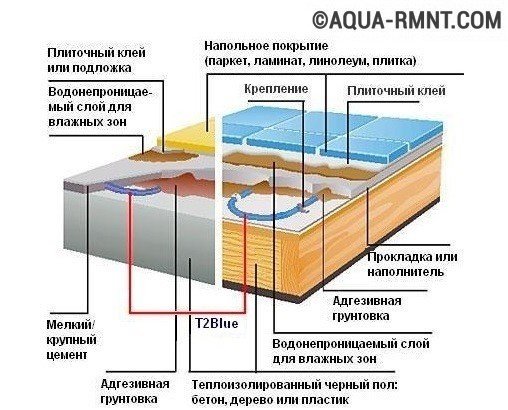

Pay attention to such a feature of the warm floor system that its functioning is accompanied by heat propagation in all directions, therefore, not only the surface of the floor of the heated room will be heated, but also a concrete base with which heating elements come into contact.

In order to minimize heat losses and prevent heating slabs, under the warm floor, thermal insulation material is mounted. The heat insulation shields heat streams, reflects them and sends the heated zone. Based on what room is heated or not heated, is below the level relative to the room in which the warm floor is installed, the type and thickness of the thermal insulation is selected.

An important stage of arrangement of the floor heating system is the installation of thermal insulation on which the heating elements of the warm floor are stacked

With the arrangement of electric heating floor in the apartment of a multi-storey house, where heated rooms are heated below the floor, a foil rolled thermal insulation material of a small thickness of about 3-4 mm is applied. The insulation bands are unfolded, carefully docked and fixed using a stepleron to the base base to prevent the material shift relative to the floor surface. Additionally, you can smoke the joints of the insulation bands by assembly tape.

The arrangement of the warm floor in rooms adjacent to unheated zones requires the installation of thermal insulation with a thickness of about 10 cm

In the case when the warm floor is laid in a private house, where the heated room may be over unheated, a foam or other slab insulating material with a thickness of 5-10 cm in combination with a heat-reflecting layer of foil is used as thermal insulation.

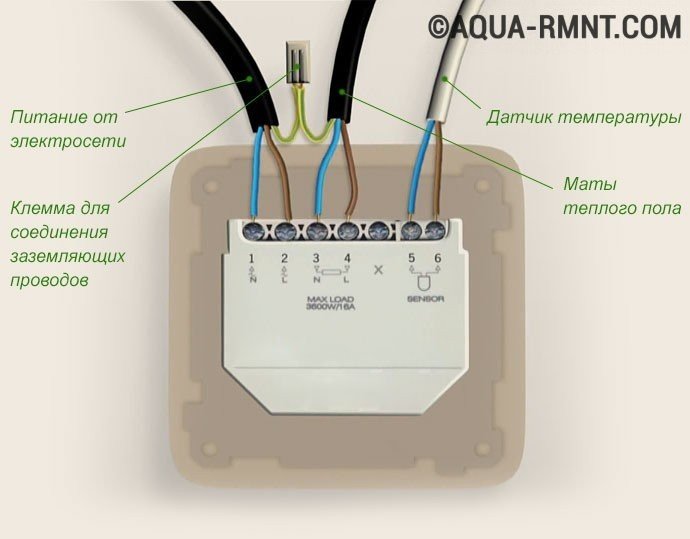

Connect the thermostat and temperature sensor

Before starting to install the heating elements of the heated floor, you must install the thermostat and connect the temperature sensor to it. The thermostat, with which the temperature mode of the warm floor varies, is mounted on the wall in a convenient location, at a height of at least 30 cm from the floor surface. The device measuring the current heating temperature is the temperature sensor, it is laid in the thickness of the warm floor at a distance of 50-70 cm from the wall on which the thermostat is placed.

Heating heating control is carried out using the thermostat, to which heating elements and temperature sensor are connected.

The circuit of connecting the electric heating floor involves the eyeliner to the thermostat of the cable, which comes from the heating elements of the warm floor, the corrugated tube with the temperature sensor inside and the wires from the central power grid. When the warm floor is turned on to heating mode, the indicator should light up on the front panel of the thermostat, while the heating elements of the warm floor will begin to generate heat.

Laying heating elements of a warm floor

Laying the heating cable is performed with a fixed step so that the floor plane is evenly warmed.

Electric flooring technology provides for the laying of heating elements with retreats from the walls of about 5 cm, from the heating devices - about 10 cm. Based on which option of the warm floor is selected - cable, cable based on or infrared, styling of electric heating floor is performed throughout Room area or only in that part of it, where the placement of furniture, plumbing devices or other interior items is expected. It must be remembered that the cable warm floor is not laid under the furniture and plumbing. Thinner thickness - film infrared floor, can be mounted in any zone, regardless of the placement of floor elements of the arrangement of the room.

Film infrared warm floor is characterized by the simplest scheme of laying and mounted under any floor covering

In the process of installing infrared or cable warm floor on the grid, the mounting of the bands with heating elements to the base of the floor is performed using bilateral tape, the mats are connected to using the assembly tape. When laying a cable warm floor, a segment of a mounting ribbon is mounted to the base surface with a pitch from 0.5 to 1 meter using dowels or screws, after which the heating cable is laid out with a specified step and fixes on the tape.

Electric warm floor can be installed even under such a "capricious" flooring, like parquet

The layout of the heating cable is performed in the form of a "snake", where the step between the turns is set at least 8 cm, but in order to accurately decide on this distance, it is possible to calculate it in this way: 100 multiplying the area of \u200b\u200bthe room and divide the heat-mall cable.