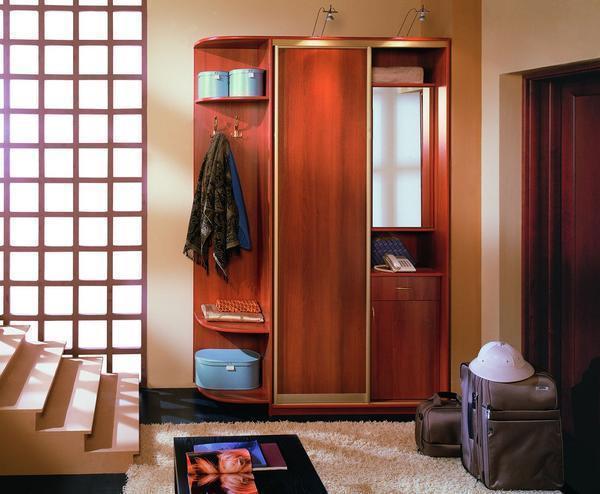

Not every cabinet in the corridor can be made independently. For example, the popular radius cabinets today is very difficult to make without proper skills and experience. Designing such a wardrobe can only a professional. But simpler designs, the schemes of which are not different by some difficulties, can be done both.

Stages of work: the wardrobe in the hallway do it yourself

The work, of course, is not fast. It is necessary to act according to plan, step by step. Focusing on the plan, you will not miss anything, you will not bet, you will be a guide to action.

Phased work plan:

- Selection of material for the future cabinet;

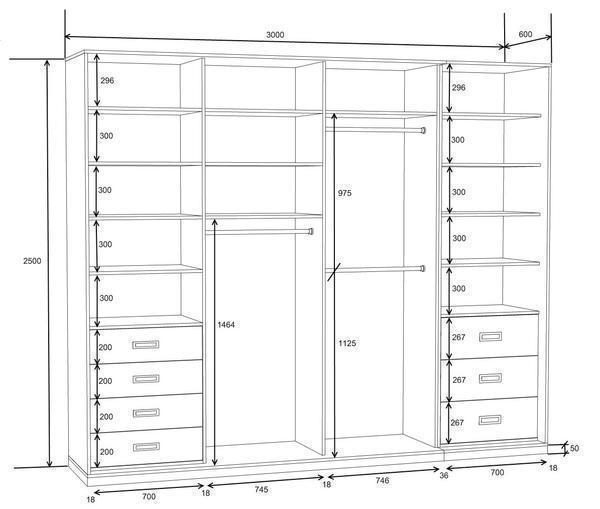

- Defining content - We need a description and drawings;

- Door design, including selection of suspension option;

- The method of suspension of the shelves is selected;

- A niche for an embedded cabinet is prepared;

- Measuring measurements, drawing;

- Acquisition of fittings, materials, as well as cutting blanks;

- Assembly of a cabinet with installation of internal lighting;

- Exterior decorative finish.

It turns out that the work begins not even with the definition of the design of the future cabinet, but from the selection of the material. After all, the principle of manufacture depends on it, and with different materials will have to work in different ways.

Wardrobe in the hallway with your own hands: Material selection

The tree is considered traditional, and now very prestigious material. But is it successful for the wardrobe? Judge for yourself, humidity in a niche, no matter how cool, will be higher than the average, the tree will inevitably begin to brew. Well, the decorative role of the tree in the case of the wardrobe is also doubtful.

But if you decide firmly - a tree, and nothing else, choose a long wood, without bitch, swees and cracks, a weathered and well-soaked olifa, and more VPE (water-polymer emulsion).

The following type of material is plasterboard. It is easy to work with it, it's cheap, but also for the fragility of this material should not forget. Yet it is intended for finishing work and can not be part of the carrier system. That is, he cannot hold something on himself - it should keep him something.

The most suitable materials are the laminate, DVP and MDF. These materials include the beneficial properties of wood, but they are insensitive to the gradient and moisture drops. DVP take medium or high density.

Filling: wardrobe in the hallway with schemes

The filling or internal filling of the cabinet is its internal layout. Today it is easy to find that optimal option that will meet all your requests. Many examples on the Internet are filling options shown from different angles. It is very convenient if you yourself have not yet decided what filling will be.

The following rules operate in content:

- Raw put to the side, separately;

- The right and small must be in front of the eyes;

- Dry lay higher;

- And the valuable should be in the boxes.

Consider at the examples. Wrong will make a section for outerwear in the middle. Then the dampness from it will definitely go to the parties. If you make a section of the side, moisture from the clothes will head out.

We compile a project of a wardrobe in the hallway

Of course, the process of creating projects has simplified - there are many Internet services, where using the specified values, the program creates a project. You can take a ready-made project that suits the features of your hallway. But there is another option.

How to order a cabinet "from scratch" in a particular company, it will be cheaper to get ordered blanks. Many furniture makers today have robots with computer control - this acquisition pays off well. In a word, no matter how the furniture workshop was not equipped, but in almost every city he offers the service of cutting blanks. And this significantly saves your funds.

All the same, the material makes the material at wholesale prices, and counting on a total area, percentage 20 you save exactly, rather than the material would be purchased in retail. And there are also discounts on trimming. Also, when sawing, such a service is proposed as the edge.

Fastening shelves in design

The most favorable way of fixing shelves in this case is on trimming a simple plinth. Plinth from MDF What only today does not happen, of different sizes, textures and profiles. And so that the fasteners of the shelves did not rush very much into the eyes, take the plinth segment shorter the depth of the shelter somewhere on a third. And the end can also be cut off.

Similarly, you can mount the upper and lower partitions in the cabinet (to the floor and ceiling). Only the segments of the plinth are not shortening. If you take the ceiling plinth of a small size, their ends will completely close the upper and lower guides. Very durable design is formed together with the same way fixed shelves. And such a design will support the boarded floor of the seed (and the weight of the door contributes to that).

Sliding wardrobes in the hallway with your own hands (video)

This, of course, not all moments in the manufacture of the cabinet, but the most perhaps important. Soberly appreciate your capabilities, think, maybe some stages still entrust professionals. And do not refuse video lessons that turn out to be very useful.