Modern household linoleum is very different from the coating, which was produced at the end of the last century and the beginning of the two thousandth. Now it is a safe material with high technical and operational qualities, which is not inferior to more expensive floor coverings.

A variety of assortment at the same time surprises and unwittingly enters into a stupor. Only in the budget segment there are more than three types of material with a dozen different characteristics. We will understand in more detail which linoleum is better for an apartment.

Requirements for domestic flooring

The choice of facing materials is made according to a number of criteria.

A typical one-room and multi-room apartment consists of several types of premises: for sleeping, leisure, personal hygiene, household needs, moving and storing objects.

In each of the premises, the load on the floor is different and depends on the degree of permeability, the amount of furniture and the conditions that are created during the life of the residents. It is worth remembering and taking into account when choosing linoleum for each of the rooms separately.

In general cases, the requirements for linoleum are as follows:

- safety - the coating should be environmentally friendly, not emit harmful substances, not be a hotbed of harmful bacteria and prevent their spread;

- wear resistance is a basic requirement that applies to any lining. The material must be durable, not scratched, withstand the load of abrasives;

- strength - heavy furniture and accidentally fallen objects should not cause severe damage to the facial layer;

- ease of care - the surface of the floor should include the possibility of wet cleaning with detergents. Moisture absorption and increased slipperiness are excluded;

- simplicity of laying - the material should have contributed to the fact that the buyer with his own hands (after reading the instructions) to prepare the old surface and linoleum flooring.

Compliance with these points guarantees, especially in the case of linoleum, that the floor will not cause significant harm to human health. This is especially important for families with babies and small children.

What kind of linoleum is better

PVC linoleum universal coating for use in apartments and houses

There are several classifications and varieties of linoleum. We will consider the classification of domestic varieties only, since industrial variants are not intended for use in an apartment.

The simplest and most correct from the point of view of understanding is the separation of material depending on its scope of application. This sorting allows you to understand which linoleum is better, which coating is suitable for a particular room, and which one is better to refuse.

Among the linoleum, which is better to lay in the apartment, can be identified:

- natural - linoleum based on naturally raw materials: recycled wood, cork flour, coniferous resins, flax oil, lime, natural dyes. The coating is completely environmentally friendly and safe. It has a long service life, high strength, good wear resistance and aesthetically pleasing appearance;

- household - an artificial covering on the basis of polyvinyl chloride, chemical stabilizers and fillers. It has average technical quality, calculated for 7-10 years of careful use. Possesses low heat conductivity, resistance to moisture and aggressive substances. The total thickness is 1-2 mm, the thickness of the protective layer is 0.15-2 mm, wear class 21-23;

- semi-commercial - the coating is almost completely similar to a household variety of linoleum. The total thickness is 2-3.5 mm, the thickness of the protective layer is 0.3-0.5 mm, wear resistance class 31-34. The service life in a residential area of \u200b\u200bat least 12 years;

- commercial - is available in various variations, but for an apartment it is better to lay a PVC-based coating. It is an improved version of semi-commercial linoleum. That is, the material has even more impressive characteristics. In everyday life can serve up to 15 years or more. The total thickness is 2-4 mm, the thickness of the protective layer is 0.7-0.8 mm, 41-43 wear resistance class.

The combination of different types allows you to more finely choose the floor covering, focusing on the specific purpose of the room. It also saves money, since it does not make sense to lay a more wear-resistant coating where its qualities will not be used.

Specifications and quality

The main technical characteristics that will help you to understand which linoleum is best for the home are the wear resistance class, the thickness of the protective layer, moisture resistance, and toxicity. In addition, materials on additional safety features can be considered: fire hazard class, flame spread, flammability.

Wear resistance class is the first thing you should pay attention to when choosing a material

According to the European standard EN685 wear resistance is marked with a digital code, which is marked on the pictogram next to the schematic drawing. An example of the pictogram is shown in the photo above.

The first number in the code means:

- 2 - residential premises;

- 3 - office and commercial premises;

- 4 - production facilities.

The scope of linoleum does not always indicate that it is in this area that the coating should be laid. Many manufacturers have a lining of a commercial type, which they themselves recommend for use in rooms with a high load.

The second number indicates the degree of load that this product can withstand. It is denoted similarly from 1 (low) to 4 (very high).

The thickness of the protective layer is the second important indicator that is better taken into account when choosing. The protective layer determines the strength of the material and its resistance to abrasion.

Gradation of the thickness of the facial layer:

- up to 0.2 mm - for impassable premises intended for storage;

- 0.2 mm - impassable room for sleeping and leisure;

- 0.3 mm - residential premises with an average cross;

- 0.5 mm and higher - for rooms with high traffic and load.

To indicate other characteristics, they are assigned an appropriate alphanumeric code. Toxicity is indicated by the capital letter “T” and a number from 1-4. The smaller the figure, the less the ability of linoleum to evaporate and decay into harmful chemicals.

Fire hazard class in capital letters "KM" and the number from 0-5. It includes such characteristics as the spread of fire, flammability, smoke, etc. Their designation is similar, that is, the smaller the number indicated next to the capital letter, the safer is linoleum.

Remembering all the additional characteristics is not necessary, the main thing to remember about this rule. If necessary, you can make a small list of what is worth more detailed consideration.

Covering for a bedroom and the nursery

In the children's room and the bedroom, you can use the class 23 class view

In the bedroom and rooms designed exclusively for sleeping and private leisure, the load on the floor is very low. The person uses the premises strictly for the intended purpose, and the useful area of \u200b\u200bthe premises is quite small.

For a bedroom it is better to choose household linoleum 23 classes 2 mm thick. You can choose a coating on a heat-insulating basis, which will make the floor warmer, and being in the room comfortable.

In the nursery, it is most important that the material is safe. Optimum laying of natural linoleum of the minimum thickness. If the child is very active, it is better to choose a household type based on PVC.

For both premises, Tarkett's under the trademark Europe Akron 6 is well suited. The total material thickness is 3 mm with 0.25 mm of the face layer, which makes it possible not to be afraid for the safety of the material even with increased activity of children. The cost of the material starts from 340 rubles / m2.

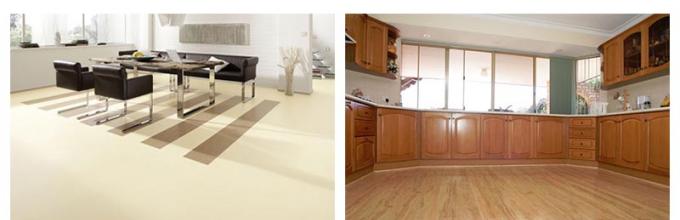

Coverage for the hall and living room

The living room and the hall are narrowly focused rooms where a person spends his leisure time, meets with his family and friends. The load level varies greatly and depends on the social activity of the person, the number of residents and family members.

In general cases, we can recommend semi-commercial PVC linoleum class 31-32 with a thickness of 2.5-3 mm. The presence of thermal insulation and anti-slip coating will be only a plus. The use of natural coating is irrational due to the high cost.

For example, it may be Tarkett linoleum from the Moda collection, Colibri, Iskra. It is a moisture resistant material with a thickness of 3.5 mm and a thickness of the face layer of 0.6 mm.

Coverage for the kitchen and hallway

In the kitchen and hallway, it is desirable to lay wear-resistant linoleum class 33

Floor cladding in the kitchen, hallway and corridor faces the most adverse conditions. In the kitchen there is a risk of ingress of aggressive substances, moisture, heavy objects falling, etc.

In the hallway and the corridor high abrasive load. Dust, sand, dirt in the warm season. Moisture, water and snow in autumn and winter. Moreover, these rooms do not have a large area, which also affects the rate of abrasion of the cladding.

Optimally, if it is semi-commercial PVC linoleum class 33 for the kitchen and commercial homogeneous coating 34-43 class for the hallway.

For example, it may be facing from Tarkett IQ Monolit Cmoni. This is a homogeneous linoleum with a thickness of 2 mm and 34-43 wear resistance class. The average cost of 900 rubles / m2. You can choose a simpler coverage costing from 600 rubles / m2.

Covering for bathroom and toilet

The bathroom and the bathroom are personal hygiene rooms. There is a risk of ingress of water and constant high humidity. Oddly enough, but the load in these rooms is high due to the very small area of \u200b\u200bthe room.

It is best to lay moisture-resistant heterogeneous commercial linoleum at the lowest cost. This material can be purchased from 400-450 rubles / m2 from some manufacturers, as the material has a small width.

According to the binder material, modern linoleums can be divided into five large groups: natural, polyvinyl chloride (PVC), glyptal (alkyd), colloxylin (nitrocellulose) and rubber (relin).

Natural linoleum, as its name implies, contains mostly natural components. Sometimes it is baseless and has a base, which is used as a nonwoven fabric or fabric made from natural fibers. By chemical composition, natural linoleum is the floor covering closest to the original source. After all, no wonder the term "linoleum" comes from two Latin words: linum - flaxseed and oleum - oil. The main components of natural linoleum are linseed oil, wood flour, pine tree resin, cork oak bark flour, limestone powder and natural dyes. Bearing base is also natural-jute fabric.

In addition to durability, environmental friendliness and decoration, natural linoleum also meets a number of operational requirements. It is fire resistant and does not contribute to the spread of flame in case of fire. It is easily cleaned from dust, therefore it is suitable for people with impaired respiratory system and allergies. Dry cleaning for it is comparable in efficiency to wet.

It is also important that after laying it retains its size. Thanks to linseed oil, the material has bactericidal properties and does not accumulate electrostatic charge. Natural linoleum does not fade, does not change color and structure over time, is resistant to non-concentrated acids, ethyl alcohol, fats, but is destroyed by prolonged exposure to alkali. This is not surprising if we recall that limestone is a part of it. When transporting such linoleum and working with it, it is necessary to avoid sharp bends - it can crack.

Polyvinyl chloride linoleum is produced on foamed, fabric, heat and sound insulating non-woven bases or baseless, single and multi-layered. The lack of PVC linoleum (except foam, with fiberglass base) - their significant shrinkage - up to 2% at elevated temperatures. The material has a specific smell, though it disappears with time. Glyphthalic linoleum is made on a fabric basis. It has better heat and sound insulation properties than PVC linoleum. Over time, its stripes decrease slightly in length, but increase in width. Kolloksilinovy \u200b\u200blinoleum (nitrocellulose) - material baseless, single-layer, thin. Its advantages should include good moisture resistance and elasticity, and the disadvantages - increased inflammability.

The most universal multilayer (heterogeneous) coating. The basis of the material - fiberglass. On the front side, it is impregnated with PVC paste, and a “canvas” layer of PVC of a different composition is applied to it. On this surface with the help of large printing cylinders with engraving is applied drawing. Used up to 6 colors. Finally, the pattern is fixed with a high-strength transparent PVC layer (thickness - up to 0.15 mm). On the reverse side of the fiberglass substrate is applied substrate. It can be jute, fabric, polyester or foamed PVC. According to experts, the foam substrate is optimal, having the same thermal expansion characteristics as the face layer. This avoids deformation of the surface when heated. More qualitative is the material in which the substrate is applied mechanically, not chemically.

Well, in conclusion - rubber linoleum (relin). This is a two-layer material. The bottom, backing layer is made from used crushed rubber. The role of the binder is played in this case by bitumen. The face layer consists of a mixture of synthetic rubber with fillers and pigment. Relin has excellent water resistance and increased elasticity. The last two types of linoleum in residential areas are practically not used. Another way to classify linoleum is by the presence or absence of a base.

Baseless linoleum - quite thin, from 1.2 to 1.6 mm, single-layer canvas with a pattern throughout the thickness. Such material is also called homogeneous. It is relatively cheap, most suitable for places with high levels of humidity and pollution, so it is mainly used in kitchens and bathrooms. Since it is very thin, it must fit on a flat base. This material is better to stick over the entire area. The service life of 5-7 years. Sometimes a special protective layer is applied to the surface of baseless linoleum, which increases its resistance to abrasion and facilitates cleaning the floor.

Linoleum on the basis of foam is available in thicknesses from 2 to 3.5 mm and is already a much more complex multi-layer construction. Serves up to 10 years. It is used in places of high pollution and where frequent wet cleaning is required (kitchens, hallways, bathrooms). It is not necessary to glue this linoleum over the entire area, it is sufficiently crisscross. If you can’t do without joints when laying cloths in wet areas, it’s better to brew them by hot welding with a special cord or by cold welding with special liquid compounds.

Finally, linoleums can be divided into a separate group on a warm basis. This is a material consisting of a polymer layer with a thickness of up to 1.5 mm with a printed or uniform pattern throughout. The layer is glued to the base of natural or synthetic jute or felt. The total thickness of the web can reach 5 mm. Linoleums of this group retain heat well, are rather soft and at the same time elastic. Designed for any residential premises where there is no high humidity. It is desirable to lay such linoleum with one blade without joints, otherwise water may penetrate the substrate and rot. But since linoleum is available in widths up to 4 m, such problems usually do not arise. Another feature of such materials is some expansion during operation (the so-called trampling). Therefore, when laying linoleum on a warm basis under the baseboard between the wall and the material leave a small, about 0.5 cm, gap.

Technical characteristics of linoleum

The main technical characteristics of linoleum are: resistance to abrasion and indentation, density, water resistance, flammability, heat and sound insulation properties, color indicators and a number of other more specific parameters (for example, antistatic and chemical resistance). Many foreign manufacturers prefer to explain the properties of their products with expressive pictograms. This is visual, and allows the consumer to understand the characteristics of a material without translation. Since the requirements for durability of linoleum for residential premises are very high, the optimum material is a thickness of 2-2.5 mm. It is impractical to use coatings thicker than 3 mm in the living space.

In recent years, varieties of linoleum with improved consumer properties have appeared on the Russian market. These materials are designed for premises with special operating conditions and received the generic name of commercial linoleum. Although it would be better to call them special or, say, linoleums for office space. We note, however, that such coatings can be applied with no less success in residential premises. According to the structure, a special linoleum, like a regular one, is divided into homogeneous (single-layer), heterogeneous (multi-layered) and natural.

On the scope of application - on general purpose linoleum (characterized by increased wear resistance, a variety of patterns and shades), non-slip (contains additives that increase friction), antistatic, conductive, sporty (ensures safe fall, good ball rebound and reliable grip on the sole of sports shoes), medical (substances contained in it prevent the emergence and spread of bacteria and fungi in the room) and heat and sound insulation. In a word, there are special linoleums for all occasions.

Different types of linoleum (baseless, with fabric, heat and sound insulating base, single and multi-layered, rubber) and polyvinyl chloride tiles are often used in living rooms for flooring. The popularity of this type of flooring due to the strength and hygiene of materials, they are beautiful, quiet when walking, do not require special care. Linoleum and tiles are glued to the prepared base on adhesives and mastics, the choice of which depends on the quality of the finishing material used in the work.

The right choice of flooring - a pledge of its long use. And in recent years, the Russian buyer can not complain about the insufficient range of products of this kind: for sale there are all kinds of carpet-carpets, floorboard, and laminate, and different types of tiles, and, of course, linoleum. Someone will say, they say, we know him, nothing interesting! But do not rush. Modern linoleum is a material of a new generation, fundamentally different from its not very presentable ancestor. Among the newly acquired qualities - previously unattainable environmental cleanliness.

Excellent decorative properties and strength characteristics allow linoleum to compete confidently in bedrooms and living rooms with laminate or carpet, and in the corridors, bathrooms and in kitchens - with ceramic tiles. It is not inferior to his rivals and in terms of service: most of the brands of linoleum is designed for use within 7-10 years, and some - and 30 years. Note that in order to prolong the life of the coating, it is important not to make serious mistakes both during its installation and during operation.

The variety of modern linoleum is impressive. For example, only German manufacturers produce about 250 material variants of about 100 colors. And every year there is a renewal of collections. Moreover, the changes apply not only to design, but also to the properties of products. However, despite the experienced metamorphosis, linoleum remains the most democratic flooring. Only the most upscale, its elite brands approach at prices to laminate and parquet. As for the simplicity and low cost of installation, here linoleum is still unparalleled. Two problems associated with this promising material have not been finally resolved: it does not tolerate frosts, direct sunlight, and some of its species have a specific odor.

linoleum DIY technology

The simplest version of laying linoleum - under the plinth. When fixing the coating with glue, it is recommended to use special serrated spatulas. For example, for PVC materials, spatulas with an A2 type blade provide the glue consumption of 250 g / sq. m. For natural linoleum optimal blade type B1 (glue consumption 450 g / sq. m). In addition, the consumption of glue depends on its own properties and characteristics of the floor covering.

Glue for natural linoleum - contact. This means that immediately after it is applied, material can be applied to the substrate. Adhesives for PVC linoleum, as a rule, require 5-10 minutes of waiting (“ripening”), and only then should the coating be attached. When the linoleum is fully laid, it is necessary either to roll it with special heavy rollers, or to grind it to the base using corkboard. This is done both to remove bubbles, and to improve the uniformity of adhesion of the material. The resulting bubbles (bulges) are pierced and the canvas is again rolled down or pressed down with a load for several (minimum two) days. Seams are welded if necessary (depending on the composition of the coating, a method of cold or hot welding is used).

Laying linoleum on adhesive materials is considered the most durable and reliable. Before applying the mastic surface must be cleaned from dirt and dust. The back side of the linoleum before the sticker primed the day before the start of work. On the basis put mastic or other adhesive composition. In the joints of the panels, an unsprayed strip 10 cm wide is left. After 10-15 minutes, the bent half of the cloth is glued and pressed to the base. Then also paste the second half of the cloth. There is another way of sticking linoleum: a cloth rolled into a roll up to about half the length of the front side inside. A mastic is applied to the base, and then the roll is gently rolled out and the cloth is glued to the base. In the same order paste and the second half.

The strength of gluing depends on the thoroughness of the stitching of the panels. To do this, when attaching the cloth, it is carefully smoothed by hand with the help of pieces of sacking or rolled by a roller. To remove air stitching is from the middle to the edges. Adjacent plates with a sticker initially overlap one another by 15-20 mm. Approximately 2-3 days after laying the linoleum should be finally cut and glue the edges: along the edge of the panel put a ruler and press it tightly. Then both sheets laid at once overlap with a knife are cut through with a knife. The unglued edges of the trimmed panels are carefully lifted, their back and base are cleaned of dust and a thin layer of adhesive is applied to the base. The edges of the panels tightly pressed to the base and rolled down. To prevent the knives from becoming blunt, and there is no violation of the base surface, before trimming, under the edges of the linoleum panels, lay a 2-3 mm thickness and 30-40 mm width along the edges of the linoleum panels.

To make a cutout for the riser, you need a template made of hard cardboard. The space around the pipe is measured by the square. Then the measurement results are moved to the cardboard. In the middle of a square on a cardboard a circle is drawn, the diameter of which should be equal to the diameter of the riser. The circle is cut so that a hole remains in the cardboard. This hole is transferred to the linoleum and cut. It is not recommended to apply them with a layer. Mastic rubbed with a polisher or a soft brush to shine. When washing a linoleum coating, soap can be added only in case of heavy pollution, since linoleum loses its luster and fades from soap and soda.

When gluing it is necessary to avoid the ingress of air under the coating. It is impossible to lay the material close to the walls, it is necessary to leave a small gap. In order for the glue to be applied evenly and precisely in the amount that is necessary for the sticker of each specific type of coating, it is necessary to use serrated spatulas with replaceable blades. At the same time, due to the different shape and pitch of the teeth of the spatulas, the required glue consumption is ensured.

Having pasted the covering, it is necessary either to roll it with heavy special rollers or to grind it with the help of corkboard. This is done both to remove bubbles, and for better setting. Thermal insulation of linoleum and PVC coatings is minimal, therefore it is desirable, and in cold rooms it is imperative to lay them on the insulating layer (for example, mineral wool, felt).

The service life of traditional and modern flooring largely depends on the correctness of its installation. But washing and cleaning with the use of solvents, acid detergents also harm them; they are destroyed under the constant influence of water. You can rub linoleum with a wool-free lint-free cloth, wax and water. But, despite the fact that linoleum and PVC coating are rolled materials, the styling features are still there. So when laying natural linoleum, the relative humidity of the floor should not exceed 3.5%.

Gluing linoleum has its own characteristics, since the absorption of moisture from the glue can lead to a temporary softening of the coating and a significant change in its geometric dimensions. This phenomenon was unknown when using previously used adhesives made from resins and solvents, because they immediately dried out. Modern dispersion adhesives contain up to 30% of water, which evaporates in the process of mixing glue. It partially goes into the layers under the coating, but is partially absorbed by the coating itself. Basics with low hygroscopicity give most of the water directly to linoleum. Therefore, for gluing natural linoleum, only those adhesives are suitable that seize so quickly that natural changes in the initial dimensions of the coating do not have time to appear.

Mastics for gluing linoleum and tiles

Buying flooring in the store, it makes sense to buy the necessary mastic of industrial production, completely ready for use. Acrylic dispersion glue or glue recommended by the manufacturer of linoleum is used for gluing PVC coatings. Adhesives for this type of linoleum basically have a waiting time (maturation), which is 5-10 minutes, that is, the coating can be glued only after the glue “matures” on the substrate. On the adhesive package is usually given all the necessary information about these parameters.

Mastics are paste-like compounds, including an adhesive base, solvents, plasticizers. Mastics should have good adhesive properties both in relation to linoleum and to bases, should be easily distributed with a layer of 0.3-0.5 mm thick, be resistant to temperatures up to 50-60 degrees. Store mastic in a hermetically sealed container at a temperature of 5-20 degrees for no more than two months. It is used to stick almost all types of linoleum.

Cumarone-rubber mastics come in two grades - KN-2 and KN-3. If the briquette mastic is used, before use it should be crushed and diluted with gasoline in the amount of 30 percent by weight of the briquettes. These mastics are used for gluing polyvinylchloride linoleum on fabric and cardboard basis and single-layer without base. Linoleum on a woven base and polyvinyl chloride tiles are glued to a cold mastic (such as "Bisca"), which is a solution of bitumen in white spirit and turpentine with fillers (cement) and additives (latex).

Linoleum on the heat and sound insulation base is glued to the base with the help of an adhesive prepared on the basis of CMC - Bustilat. Universal for sticking various types of linoleum and tiles are dispersion adhesives - compositions based on dispersion AK-215-23, 10% aqueous solution of CMC, 10% solution of pine rosin in xylene with fillers in the form of kaolin and talc. Dispersion adhesives equally firmly fasten linoleum to the base of concrete, cement-sand screed and chipboard.

Baseless and rubber linoleums are glued onto coumarone-neurite (dispersion) adhesives, which are solutions of coumarone resins and synthetic rubber in a mixture of gasoline and ethyl acetate with fillers and additives. Floor coverings, among which we select linoleum (natural and vinyl), carpet (on jute, polyvinyl chloride or polymer-bitumen base) and sheet cork, cannot be mounted using only two adhesives, as in the case of wallpaper. For natural linoleum, adhesives in the form of a water dispersion (Uzin-LE 2401 from UZIN, Okamul L14 from KIESEL, Super Sader Tac from BOSTIK FINDLEY) are more suitable, and for vinyl linoleum and carpet - based on PVC (Uzin-KE \u200b\u200b418, Okamul E9 and Sader flex of the same firms). Special water dispersions with bactericidal and fungicidal additive Uzin-KE \u200b\u200b2008 from UZIN and Okamul T6 plus from KIESEL have been developed for carpet on jute substrate. There are cheaper brands of these adhesives without additives.

But it is not worth saving, so that you do not have to subsequently change the coating because of the appearance of mold. The conductive adhesives Uzin-KE \u200b\u200b2428L from UZIN, Klefa fix from BOSTIK FINDLEY with graphite filler are designed for carpet and carpet tiles on a polymer-bitumen base with graphite filler, which simplifies the grounding of the coating to prevent electrostatic charge from accumulating on it. For carpeting tiles, the BOSTIK FINDLEY Sader adhesif is recommended, allowing multiple fixation of the module to be removed and stacked. Cork coating is well glued with water-based compositions Uzin-6N 276 (UZIN), Okapren KK extra (KIESEL), K12 (PUFAS), designed for porous surfaces. For all the listed coatings, you can use Maxiglue, Plastiglue NM solvent-free adhesive glues from BOSTIK FINDLEY or Uzin-KR 430 polyurethane adhesive compounds from UZIN, Okamul PU from KIESEL, Tomsit R710 from HENKEL, Colle 455 from BOSTIK FINDLEY. But they are more expensive than water three times.

When using any of the adhesives, immediately after laying the coating on the floor, roll it several times with a roller from the center to the periphery - to remove air bubbles, uniformly distribute the layer of glue and squeeze out its excess along the edges. Ceramic tiles most often fit on the cement mixture, which add a little glue. But for facing rooms with high humidity (bathroom, sauna dressing room) and water-filled containers (swimming pool, hot tub), water-resistant adhesive mixtures, such as countless HENKEL Ceresit brands or TERRACO Terra fix brands, as well as Epocolor epoxy glue, are successfully used. from BOSTIK FINDLEY.

Mixtures may be frost-resistant, with operating temperatures below -30 ° C. For dilution of the mixture instead of water, special solutions are recommended, for example, Terra bond A from TERRACO. The glue compound is supplied in six different colors and can be successfully used as a grout between the glued tiles. INDEX offers more than a dozen adhesives of different compositions, while Elastocool AB two-component adhesive holds the tile in cold temperatures down to -40 ° C and resists cracks up to 2 mm wide.

Linoleum tools

Tools for linoleum work: a knife, well sharpened, so that it does not tear the edges; ruler, notched trowel 150-200 mm wide with turned teeth 1.5 mm high and 3 mm distance between them. This spatula is used in cases where the paste spreads. For a thicker mastic, you can use an ordinary metal or wooden spatula of the desired width. The knife should be sharpened well and directed so that it cuts linoleum, and not tearing its edges. Ruler. The edges of the linoleum cut along the line. Apply long (2-3 m) and short (1 m) line. They can be wooden, precisely planed or metal. The width of the wooden rulers 50-100 mm, thickness 15-25 mm. A narrow metal ruler can be stuffed on a wooden one.

A notched trowel is made from roofing, and even better from thick steel, 150-200 mm long, with turned teeth 1.5 mm deep and 3 mm apart. The spatula is fixed in the handle. Using a notched trowel, level the mastic applied to the base of the floor. The excess mastic is moved by the blade of the spatula, and on the base only the one that passes between the teeth remains. First, the mastic takes the form of smooth grooves, and then spreads, forming an even thin layer with a thickness of 1 to 1.5 mm. Notched trowel is used only in cases where the mastic has the ability to spread. If the mastic does not spread, then it is applied with the usual wooden or metal spatulas as even as possible.

Some useful tips when laying linoleum do it yourself

The thinner linoleum, the stricter the requirements for the surface on which it is laid. Consider: irregularities of a poorly prepared base will not only catch the eye, but also significantly accelerate the wear of the coating. In addition, the base must be dry. Most floor materials (PVC coatings, natural linoleum, etc.) do not allow water to pass through. The maximum allowable moisture of the base is determined by the maximum residual moisture. It is not the same for different materials, but usually does not exceed 4.5%.

The prepared base must be thoroughly cleaned of debris and dust with a vacuum cleaner. New rolls of linoleum roll out and allow them to rest in bed, so that the smell disappears and the material smoothes out a bit. There are a number of recommendations regarding the direction of paving, but there are no uniform rules - it all depends on the size of the room and rolls, the lighting, the method of fastening the canvases. For example, single-colored or marbled stripes are laid in the direction of light - this gives the impression of a solid coating. Linoleum with a pattern placed along the room. But do not forget, when purchasing such a material, to make a reserve along the length (10–20 cm for each piece) to fit the pattern.

Once a decision has been made on the method of laying the material, proceed to its cutting. For this, it is better to use special scissors with interchangeable blades. Trapezoid blades are used for marking, and hook-shaped - for final trimming. When cutting, leave a small margin (5-6 cm) for trimming linoleum to the walls. Cutting to the wall is done only after the main cutting of the material is completed. In order to make the edge smooth, use a special tool, called wall markers.

To check the moisture of the screed, put a napkin on the cement and a plastic wrap on it so that it covers the cloth from all sides by 10-15 cm. Glue the edges of the film to the screed with adhesive tape. Put something heavy on top and leave it for 15 hours. If the paper stays dry after this time, then everything is fine, you can start laying the linoleum. If the paper has become wet, then with the laying it is worth the wait. Recall that the time of "maturation" screed - 25-30 days. Recently, self-leveling compounds have been used for leveling floors. The time of their "ripening" is 6-8 hours.

If it is necessary to glue parts of a large area from a homogeneous material (floor coverings, cladding panels, wallpaper), it is more convenient to buy ready-made glue in plastic (canister, 8-15 kg bucket) or tin (1-5 kg \u200b\u200bcan) container, and in the form of dry mixes - in a paper bag weighing 1-25 kg.

In case of repair, it is best to have on hand a cartridge with universal mounting glue “liquid nails” weighing 400 g. For periodic gluing of surfaces of one material (for example wood) it is economically expedient to purchase a tube of special glue weighing 250 g.

In no case do not neglect the operation of exposure to air for glue on the solvent, since the presence of the latter in the adhesive joint leads to the formation of a porous seam, which has a rather low strength. Water-based glue is sensitive to freezing of water, therefore it should be applied at a temperature not lower than 5 ° С. The upper temperature limit for each adhesive is its own and is listed in the accompanying instructions. The easiest way to protect the seam from moisture - paint after gluing.

For hot-setting glue, it is most convenient to use a hair dryer as a source of uniform heating with hot air up to 80 ° C. Curing at a higher temperature can be done with an infrared source. Consider the glue consumption when installing all materials based on wood (chipboard, fiberboard, MDF), drywall, rubber, foam, porous wall panels are much higher than for rigid plastics, including carpet base and ceramic tile.

Despite the fact that today presents a huge selection of flooring, the most popular is linoleum. By purchasing this material, the consumer for a relatively small amount gets a reliable and solid foundation, which is not afraid of moisture or mechanical damage. Next, we analyze in more detail the advantages and disadvantages of this material. The article will also tell you how to buy linoleum in an apartment.

Main characteristics

Until recently, the main disadvantage that prevented the choice of linoleum for an apartment as the preferred material was considered to be a large number of synthetic components in it. However, today the production uses more and more natural ingredients. Therefore, to the question of consumers about whether linoleum is harmful in an apartment, manufacturers with a positive answer negatively. One of the most important indicators of a material is its strength. Quality linoleum is not susceptible to mechanical damage from a fallen object or the heels of women's shoes. Thus, another important indicator is the thickness of the linoleum. For an apartment, an average value is preferred. If the flooring is experiencing increased loads (for example, in the hallway), then it is better to get a more dense material. Equally important is the elasticity of the coating. Due to this property, it is almost impossible to damage it during operation or installation.

Ease of installation

For home craftsmen it is important that the material can be easily laid. The process of covering the floor with linoleum does not require special knowledge or special skills. At the same time installation passes without dust and dirt. Linoleum flooring does not require significant financial costs, and it is quite possible to cope with the work yourself.

Appearance

This indicator is also important. Technologies that are used in modern production, allow to obtain various combinations of patterns, colors and textures. Thanks to a wide range, you can choose a coating for any style of interior. Linoleum is perfectly combined with various materials used in interior decoration.

Structure

Linoleum is produced in two types. The material may be hetero or homogeneous. The second type of coating is small. It is usually from 1.5 to 2 mm. Drawing on the material applied through the pass-through technology. Due to this, the pattern is not erased during operation. It is this quality that makes it possible to stack this type of material in places subjected to intensive loading. If you need to buy linoleum for the kitchen, then preference is better to give a homogeneous coating. Perfect material with such a structure for the corridor. Better quality is considered heterogeneous linoleum. Its density is much higher than that of homogeneous. It can be up to 6 mm. In the structure of the material there are several layers. The backing is made of polyvinyl chloride foam. It is followed by a layer of fiberglass. It is strong enough and performs the function of reinforcement. Next comes the PVC layer. Drawing on it. The final is a lacquer coating. It contains bactericidal impregnation, which has, among other things, a protective and decorative purpose. Heterogeneous linoleum is perfect for bathrooms, balconies, dining rooms. Often stack flooring with such a structure and in the hallways. Mixed material is also available. This linoleum also has a multilayer structure. The base material is homogeneous. PVC layer is glued on top, then fiberglass and polyurethane film. The latter protects the coating from mechanical damage. If you want to lay linoleum in a room for rest, then the material of the mixed type will fit perfectly.

"Domestic" coating: basic characteristics

Speaking about how to choose linoleum for an apartment, it is necessary to say about some of the most important characteristics. The most important is the magnitude of the load. For rooms in which special requirements are not imposed to a floor covering, household linoleum perfectly will be suitable. Its thickness is relatively small, and the density is estimated as average. Weight per 1 m 2 can be in the range from 1.25 to 2.25 kg. The strain rate can be up to 2 mm. Installation of the coating is quite easy. Its undoubted advantage is that when it is twisted into a roll, no cracks form on it. In addition, household linoleum has a high level of sound absorption. Purchase material can be 1.5-4 meters wide. Typically, this type of coating is used in bedrooms.

disadvantages

As practice shows, household linoleum perfectly attracts dirt. At the first stage, small gray islands can be seen at the rapids. Over time, there are numerous “paths” that clearly show the ways in which the inhabitants of a dwelling usually walk. This type of coverage in the store is very easy to learn. The cost of the material is the lowest. In some stores, the price per meter does not exceed 100 rubles.

"Commercial" material type: characteristics

Many consumers ask: "How to choose linoleum for an apartment so that it serves for many years?" Experts give an unequivocal answer to this question: "A commercial type of material follows." The cost of coverage will, of course, be more expensive (from 500 rubles). However, as a result, you can purchase high-quality and durable coating. This category contains a huge variety of textures and patterns. In the range presented by manufacturers it is quite possible to find coverage for any room in the house. Often acquire commercial linoleum for the kitchen and hallway. In these areas, the flooring must withstand increased loads, be moisture and wear resistant. The service life of the coating is at least 25 years. The material has a high degree of sound absorption, providing acoustic comfort in the room. The degree of material deformation is no more than 1 mm. Coverage can be purchased in a width of 2.5-5 m.

Semi-commercial type of material: characteristics

According to many experts, this is the best linoleum for the apartment. The average cost per meter of material is within 250 rubles. The range is presented as products of Russian and foreign companies. From the name it becomes clear that semi-commercial linoleum is a cross between household and commercial. This material is very practical. It is thinner than commercial. But it makes installation much easier. At the same time, its quality is much higher than that of domestic. Due to this semi-commercial linoleum is perfect for bedrooms and children's rooms. The term of its operation is about 10-12 years. The surface of the material is covered with a special protective film. This makes it quite easy to wash off the dirt using a regular sponge and soap solution.

Specialized material types

In addition to the above, manufacturers produce varieties of linoleum with any pronounced properties. Among them are:

Base material

How to choose linoleum for an apartment correctly? What should be the material - with the base or without it? It should be said that linoleum was previously produced on a felt basis. This material retains heat very well. In addition, walking on such a coating is nice - it is soft. Thanks to the felt base, the material perfectly absorbs sound. But the disadvantage of such a framework is too short service life. Moisture penetration and mechanical damage are especially harmful to felt. In exchange for this natural material came synthetic. The latter have all the necessary characteristics. At the same time, the artificial base is devoid of the disadvantages inherent in natural materials. Synthetic seamy layer may have a different thickness. It all depends on the purpose of the room. So, for example, coverings with a basis for bedrooms, kitchens or nurseries are issued. Besides the fact that the backing layer improves the heat and sound insulation properties of the material, it evens out minor surface defects. As a result, the flooring becomes, if not ideally even, then very close to it.

Material without base

This type of coating usually fits on a well-prepared surface. Today there are a large number of self-leveling floors "under linoleum." In fact, the surface must be perfectly flat, but without a protective coating. This task is exactly linoleum. Material without a basis to determine quite easily. First of all, this coating has a large weight. The material also bends poorly. Very often it is covered with a thick laminated layer. In this case, the problem of which linoleum to choose for an apartment, with or without a foundation, is solved taking into account the state of the floor.

Material color

Speaking about how to choose linoleum for an apartment, it should be said that the material should fit organically into the interior. Today, the range of coatings is quite wide. On the market are models of a wide variety of colors. Linoleum in the apartment (photo coverage can be viewed in the article) should match the range of the purpose of the room and its design. For example, in the bedroom it will look good covering soft warm tones - golden, beige, cream. It is preferable to choose a material without a pattern, monophonic or with soft transitions. The most successful option could be an imitation of the surface of a natural marble or wood coating. For the living room fit both bright and rich, and soothing shades. Original look linoleum with an ornament or pattern. Bright colors are suitable for a children's room. In combination with a variety of contrasting pattern, they will look great.

Which manufacturers should be preferred?

A successful combination of pattern and color coverage - a definite plus. However, these characteristics are not essential when choosing linoleum. Of particular importance is environmental friendliness, material safety, as well as its compliance with quality standards. Choosing a cheap coating, the composition of which is unknown even to the manufacturer itself, there is a high probability of getting serious diseases as a result of exposure to toxic secretions. By purchasing a model of a proven company, the consumer is guaranteed to receive a quality product, which, without fear, can be used in any room at home. Today, Tarkett products are popular among domestic flooring brands. This company uses only modern materials and technologies in production. Production conforms to all sanitary and hygienic and fire-prevention standards. Products, in addition, are distinguished by a variety of design solutions.

Thanks to a huge assortment, it is easy to choose linoleum. Despite the large number of other flooring, linoleum is still quite popular. And this is not surprising - it has an interesting design, is characterized by low cost and ease of installation.

This flooring is characterized by springiness, softness and sufficient strength.

What to look for when choosing how to choose the right quality linoleum for your home?

Linoleum selection parameters

When choosing a flooring, consider the following parameters.

- Does linoleum fit the room?

- The number of residents, the patency of the place and the load on the floor.

- Does the coating have the necessary properties: thermal insulation, noise absorption, moisture resistance, anti-static, anti-bacterial qualities.

- Does linoleum fit into the design of the apartment. It can be with an abstract pattern, monophonic or with imitation of various textures - fabrics, wood, stone, tiles, etc.

What type of linoleum to choose?

First you need to figure out what kinds of it exist. There are many varieties of linoleum made from synthetic and natural materials on the market today.

There are the following types of this flooring:

- natural;

- colloxylin;

- rubber;

- glyphthalic;

- polyvinyl chloride.

Natural linoleum

For the manufacture of natural linoleum use:

- pine gum;

- cork flour;

- wood flour;

- limestone powder;

- linseed oil;

- natural dyes;

- jute fabric.

Natural material linoleum is excellent for living spaces. It will appeal to people suffering from asthma or allergies and will be an excellent option for the children's room.

The advantages of natural linoleum

- Abrasion resistance.

- Environmental friendliness.

- Do not fade from the sun.

- Does not change color and structure over time.

- Has bactericidal properties.

- Does not support burning.

- It is easy to care for him.

- A wide choice of various coloring (with monophonic or marble drawing).

disadvantages

- Relative fragility (when bending the linoleum cracks may appear, you can not throw it during transportation and installation).

- It is undesirable to apply the coating in a room with high humidity - bathroom, toilet.

- Big enough price.

Polyvinyl chloride linoleum is made on a woven or non-woven insulating base. This coating can be both multi-layered and single-layered.

The advantages of PVC linoleum

- Low thermal conductivity.

- Dielectric properties

- Environmental friendliness.

- Not rotting.

- A wide range of colors, patterns and patterns.

- Easy installation.

Minuses

- Sensitivity to high temperatures.

- Instability to alkalis, fats and chemical solvents.

- With a decrease in temperature, the elasticity of linoleum decreases sharply, it can crack.

Synthetic linoleum is:

- semi-commercial;

- commercial;

- household.

Linoleum for home (household) - cheaper, thin and not very durable (its service lines are no more than 3-5 years).

Commercial linoleum (for work and office space) has the highest wear resistance, it is the most thick and durable, can serve for more than twenty years.

Semi-commercial linoleum is used either in homes and apartments with high traffic, or in commercial premises with small traffic. He serves 7-20 years.

There are a huge number of different types of PVC linoleum: antistatic, noise absorbing, electrically conductive.

Alkyd (glyptal) linoleum

This type of linoleum is made by applying an alkyd resin on a fabric base. Its advantages include good heat and sound insulation properties.

The disadvantages include brittleness and, as a result, complexity in laying, as well as a tendency to the appearance of kinks and cracks. Before laying this linoleum it is necessary to hold it in a warm room, otherwise it may be deformed - its width will increase, and the length will decrease.

This type of linoleum is made from nitrocellulose. It is usually produced without a base.

pros

- Elasticity.

- Moisture resistance.

- Decorative shine.

- Fireproof.

Minuses

- Tendency to shrink.

- Sensitivity to temperature changes.

This two-layer linoleum. Its lining is made of old crushed rubber with bitumen. The front (top) layer is made by mixing rubber, filler and pigment.

pros

- High moisture resistance.

- Elasticity.

Minuses

In its composition, linoleum contains substances harmful to humans, because it is not advised to lay it in residential areas.

How to choose linoleum for different rooms

Linoleum is classified and labeled in accordance with the purpose of the premises.

The first digit varies from 1 to 4:

- 1 - rooms with minimum traffic;

- 2 - production facilities;

- 3 - office space;

- 4 - residential premises.

The second number indicates the expected load:

- 1 is the lowest;

- 4 is the highest.

For example, in the bedroom and the office is suitable cover 21 class. In the kitchen or in the hallway for a family of 4-5 people a floor covering of 23-24 class or 31-33th floor will suit.

Linoleum in the hallway, corridor, kitchen

These rooms have a sufficiently large permeability, here we advise you to lay 3-millimeter linoleum.

In these rooms you can use polyvinyl chloride household linoleum, but even better, semi-commercial. As for texture and color, linoleum for ceramic tiles is a traditional solution for these rooms.

In the living room

The living room has a moderate permeability, for it linoleum with a thickness of 1.5 mm is the best option.

This room has a small probability of mechanical damage, because here you can lay a PVC linoleum or inexpensive household linoleum made of polyester.

Linoleum in the bedroom

The bedroom is a room with low traffic, it needs thinner linoleum - from 1.2 to 1.5 mm.

For the bedroom, the most optimal is a household polyester linoleum or a coating on a foam base of polyvinyl chloride.

In the children's room

Children's room has an average degree of permeability, but a large proportion of the probability of mechanical damage.

In the nursery, you can lay household linoleum from polyvinyl chloride foam, and preferably semi-commercial, with a protective top layer of not less than 0.25 mm.

Linoleum on the balcony

Linoleum does not tolerate changes in temperature and sunlight. Any of its views will quickly deteriorate when used on a veranda, in a garden gazebo, in an unheated loggia, or on a balcony.

How to choose the decor and colors of linoleum

Linoleum has a huge range of colors and designs. In production, it is given juicy bright colors that do not fade over time. Synthetic linoleum has even better decorative possibilities. It imitates ceramic tiles, wood or stone very reliably.

Recently the decor which imitates a parquet board or a parquet is in great demand. Linoleum can perfectly reproduce cherries, beech, oak, as well as exotic species - rosewood, zebrano, bamboo.

The flooring reproduces the texture and pattern of natural wood. Linoleum with imitation of solid wood and mosaic wood boards is in good demand. Unusual colors and fantasy decors suit extraordinary and courageous people.

Fans of experimenting will be able to pick up abstract and original geometric patterns. Very effective linoleum with imitation of a stone - marble or granite.

You can find coatings that can reproduce artificially aged materials - shabby stone or wood with traces of time.

When selecting linoleum for the house should adhere to the following tips.

- Trust your sense of smell - the sharp smell of linoleum indicates its poor quality. It may contain additives that are harmful to health. Good quality natural or synthetic linoleum practically does not smell.

- High-quality linoleum does not have greasy shine, its design should look natural and be distinct. The coating must have at least five layers.

- Linoleum canvas width should match the size of the room. But you need to take coverage with a margin so that you can adjust the picture and cut the canvas at the joints. When calculating, be sure to consider the presence of thresholds, niches under the batteries and other projections in the room.

- We advise to buy linoleum not in the market, but in a heated room. In addition, the store is more convenient to check its quality.

- Be sure to check that your coverage complies with safety standards. Linoleum, which has passed a special examination, must have appropriate labeling. The seller must have a hygienic certificate.

- Check the quality of linoleum need to roll out. So you can see the bumps and waves on the surface or areas with exfoliated top film. These figures indicate a marriage. Such coverage can not be bought, because the existing irregularities can not be smoothed.

- When buying the same linoleum for several rooms, better buy it in one piece. But first calculate whether it will work to bring a long roll into the room and whether it can be transported by stairs and narrow openings.

- It is strictly forbidden to fold the canvas in half. We do not advise you to glue the adhesive tape to the front surface, as there remains an adhesive residue that is difficult to remove. Linoleum must be folded face down. If it is folded face out, then you need to wrap it with a protective film.

- Choosing linoleum, give preference to the coating with a special protective layer. This coating washes well and keeps a great appearance for a long time.

- If possible, see samples of linoleum in the room in which it will lay. This will help to more accurately find the appropriate colors in the interior.

- Purchase linoleum need one batch. Different batches often differ in color, even when their articles are the same.

Video: how to choose linoleum

Linoleum, which is one of the most popular materials for arranging floors in a residential area, is very widely represented in many trade enterprises, which allows you to design the interior in strict accordance with the tastes of every homeowner. Knowing how to choose linoleum correctly, you can choose such a variant of this universal flooring, which at the same time would correspond to personal preferences and have excellent performance characteristics.

So, with what moments you should decide when choosing linoleum. We tell.

The first question: where do you put it?

Since the qualities of linoleum variants offered for sale differ considerably in their qualities, depending on the place of installation, they can be divided into the following groups:

- for flooring in - here it is best to use polyvinyl chloride linoleum: the high durability of such a material, the possibility of processing it with chemicals, which is especially important when it comes into contact with fats, allows you to maintain the cleanliness and beauty of the floor covering. The presence of a protective top layer increases the degree of resistance to mechanical stress and aggressive substances;

- flooring in living rooms is better to produce multi-layer linoleum on a foam base: the presence of high noise and heat insulating properties ensures that the required temperature in the room is preserved and there are no extraneous sounds.

Drawing for the kitchen is preferable low-key, but in the rooms you can already choose a pattern on the linoleum to your taste: in flower, “under the floor” - any options in the living room will look great, emphasizing the individuality of the room, its style and the presence of taste in the owner.

Question two: what is the optimal roll width and what are its other dimensional characteristics?

Determining which linoleum to choose for an apartment, you should pay close attention to the width of the roll. Dimensions in the range of 1.5-4.0 m with a step of 0.5 m are standard. Material consumption when laying on the floor, as well as the degree of complexity of cutting and quantity (they have yet to be patched!) Largely depends on the width.

Typically, the length of one sheet of linoleum in a roll is 3 m or more, which allows you to cut a piece of the required length and thereby minimize material consumption during installation.

Coating thickness can also vary significantly: from 1.6 to 5.0 mm. The average thickness of linoleum, intended for laying in a living room, can be considered 2.5 mm.

Binder material - question three

Choosing linoleum that will fit in rooms with high traffic (corridors, rooms without carpets), you should stay on the options most resistant to abrasion. All types of alkyd linoleum with high levels of thermal and sound insulation perfectly retain their original qualities and appearance. However, their low resistance to moisture makes this option not very suitable for the kitchen.

The most resistant to moisture is linoleum, made of PVC. On the shelves of trade enterprises, it is represented quite widely. Practice shows that the somewhat higher cost of flooring of this type is a direct consequence of its improved qualities.

Color solution

A variety of colors of linoleum pleases the eye, however, and determines the complexity of the choice. Linoleum with a simple ornament ("under the parquet" in squares) is the easiest to cut. In this regard, the options for imported production differ from domestic brands in a positive way. The convenience of laying them is that the pattern on imported linoleum is often applied in such a way that the opposite edges of the roll have a pattern that is an extension of itself.

The basic rule of the choice of the ornament in the selection of linoleum - a large pattern looks most impressive in large areas, and small pattern "will play" in small rooms.

Matching the wallpaper and the color scheme of the floor creates a harmonious impression of the room. Therefore, the choice must take into account the prevailing color in the room.

When deciding which linoleum is better to choose, you should adhere to the following tips from professionals:

- It is necessary to buy linoleum a little more than it is required according to the measurements of the room under registration.

- The presence of a quality certificate can protect the buyer from a poor-quality fake, which has low hygienic and operational properties.

- Check the quality of the selected type of linoleum as follows: a small sample of his mash in his hand. In the absence of wrinkles, pronounced cracks and loss of brightness of colors, we can safely talk about the high quality of the product.

- The choice of coating samples based on foamed PVC will provide a longer service life of linoleum due to the absence of its contact with the concrete slab of the floor.

- The clarity of the printed pattern, the absence of its blurring also indicates the high quality of the material.

Orienting you to the selection of linoleum will undoubtedly help and the rating of the main brands of this flooring made up by specialists.

The following video will certainly help you to navigate the linoleum world: